Products

FIB-SEM

Nanomanipulators

OmniProbeOmniProbe CryoSoftware

AZtec3DAZtecFeatureAZtec LayerProbeTEM

Hardware

EDSUltim MaxXploreImaging

TEM CamerasSoftware

AZtecTEM

16th December 2021 | Author: Alexandra Stavropoulou

Many current development projects are influenced by political decisions related to CO2 emissions and climate change. Most countries have targets for the reduction of CO2 emissions, and this means that a lot of interesting work is being done in order to move towards making renewable energy more widely used.

As part of this movement there is a drive to reduce the emissions generated by vehicles and a number of countries have set targets for banning the availability of ICE (internal combustion engine)-powered cars in the market by as soon as 2025 (e.g. Norway). Before EVs (electric vehicles) can become more widely used than ICE vehicles there are a range of issues related to the performance and lifetime of lithium-ion batteries that need to be solved, and new infrastructure that has to be set up to support this technology.

One such challenge is in the cathodes in Li-ion batteries, which are made from nickel, cobalt, and manganese powders that are processed to make the final cathode material. Cobalt, in particular, is in high demand for battery production, and the supply of new mined material is struggling to keep up with the demand. This makes it essential to ensure that the material is not contaminated and therefore wasted.

Recently, we were involved in looking at sources of contamination in powder materials used for battery components manufacturing. We looked at CoO powder samples taken at different processing steps from the raw material at the mine to the final powder used for production.

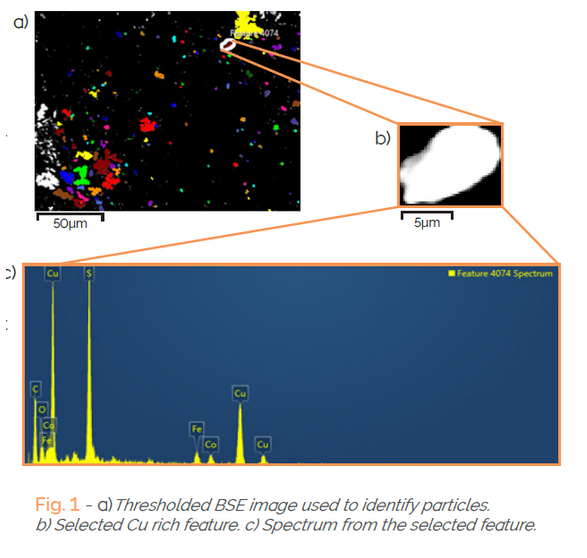

The work was carried out using AZtecFeature, which enabled us to identify and characterise the contaminants, and subsequently identify the sources of contamination. This investigation led to a level of understanding which allowed us to implement improved standard operating procedures (SOPs), so that the contamination could be consequently prevented, thereby making a better product while saving time and resources trying to remove the contamination particles from the process.

AZtecFeature is a very useful tool for this type of application as the combination of EDS and thresholding of the BSE imaging signal can easily be used to locate the contaminants and characterise them.

For more information download the full application note.

Our equipment is routinely used by companies in the battery industry for different applications in the processing chain from the mine to manufacture of the final products, with the most common applications being cleanliness for quality control, failure analysis and the characterisation of materials during R&D. SEM-based analysis adds value all along the process chain!

Consolidating the knowledge from AZtecFeature and in order to further facilitate QA/QC for battery precursor powders, we created a dedicated user profile for AZtecFeature - AZtecBattery - which helps speed up QA/QC routines as well as making the solution turnkey, while ensuring the quality of your final product and enabling minimum instrument downtime with automation. What is more, AZtecBattery comes with customisable classification schemes for undesirable particle detection, so that it can be tailored to your specific needs, and so allowing you to experiment with new formulations.

Apart from AZtecBattery, a lot of exciting work is being performed making use of the latest generation technology in our detectors and software to address the needs of the battery industry and research.

If you’re interested, you can learn more about the value of SEM-based analysis of a variety battery components in our recent webinar.

We send out monthly newsletters keeping you up to date with our latest developments such as webinars, new application notes and product updates.