Development of High Performance Steels

The development of special steels to fit the needs of these challenging applications is on going. A key part of this cycle is the characterisation of the different steels, as part of the testing process, in order to understand which of the materials characteristics give desirable material properties.

One example of these materials is TWIP Steel. TWIP (twinning induced plasticity) steels are interesting because of their outstanding materials propertied - high strength and good ductility. To use these steels in high energy absorption applications – such as for safety critical components in automotive applications requires an understanding of the impact of severe deformation on the microstructure.

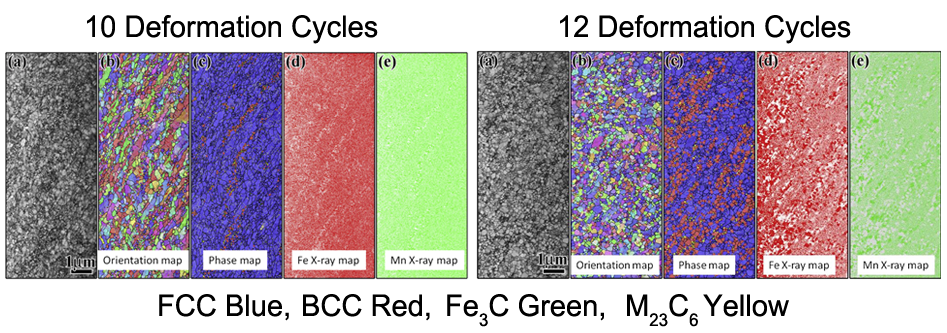

To understand how the TWIP steel would perform in an automotive crash the material was deformed in the laboratory using high pressure torsion to different strain levels. After different levels of deformation the microstructure was examined. Two factors were examined, grain refinement and phase transformations. As the grain size in these materials was so small, to achieve the required spatial resolution Transmission Kikuchi Diffraction (a variant on EBSD) was used TKD was required because in these high performance materials grain size is very small. TKD is a variation on EBSD where optimal spatial resolution can be achieved.

By studying the TWIP steel after different levels of deformation a clear difference in the microstructure was observed.

Firstly, there was a decrease in grain size this is seen in the orientation map. There have also been some phase transformations - with an increase in the amount of ferrite.

There is also a distinct chemical segregation in the more highly deformed material, and the Mn movement causes destabilisation of the austenite and formation of the Mn-enriched carbides TKD and EDS were essential in determining this evolution.

This all has a knock on effect on the material properties and enables materials engineering to develop materials for each critical application.