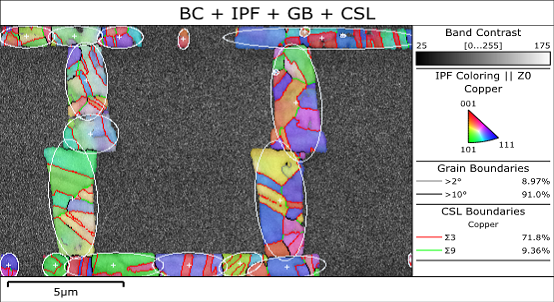

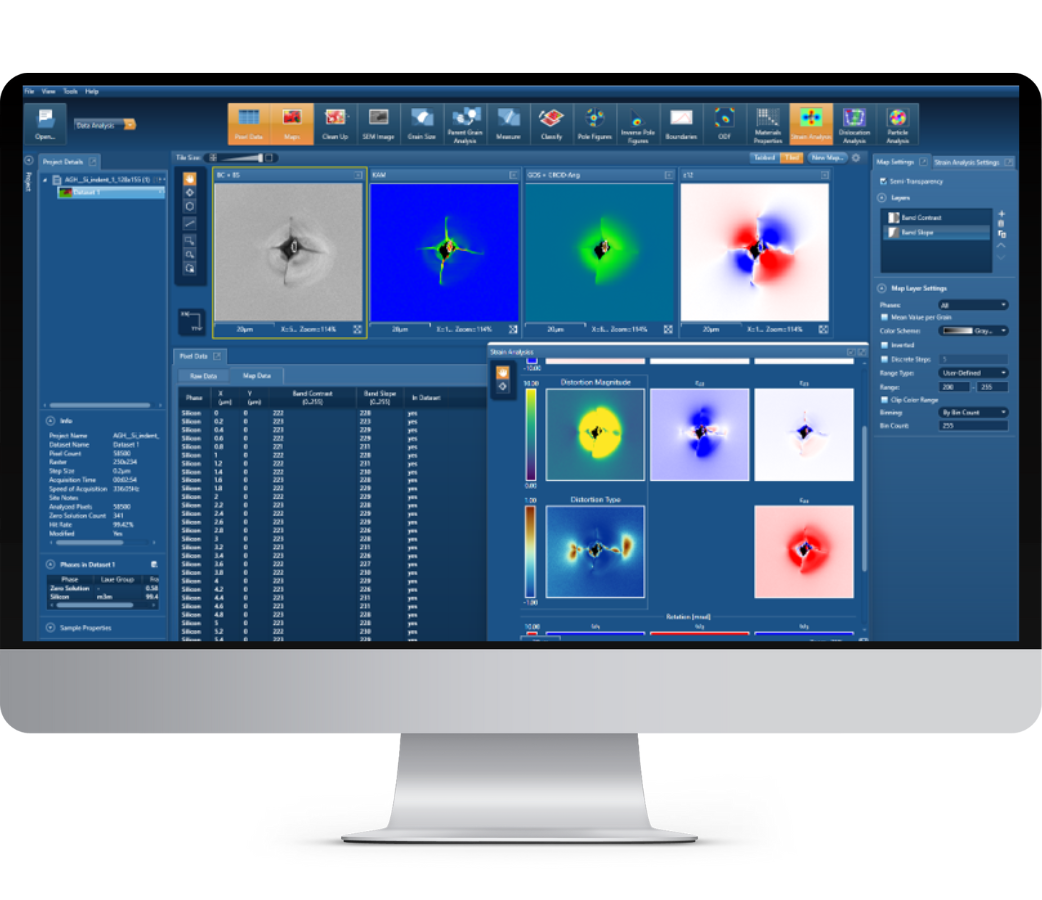

AZtecCrystal is a comprehensive software package for processing data collected using electron backscatter diffraction (EBSD). It is designed to have the ease of use necessary for newcomers to the EBSD technique, yet to have the advanced tools required for in-depth materials characterisation and diffraction pattern reanalysis required by more experienced operators. Whatever you require from your EBSD data analysis, AZtecCrystal is sure to deliver. New features for AZtecCrystal include:

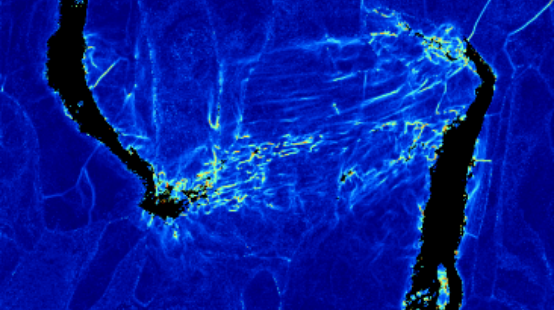

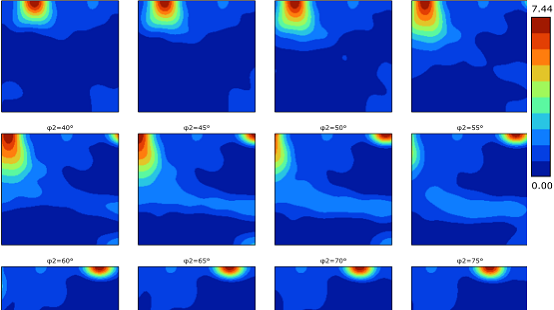

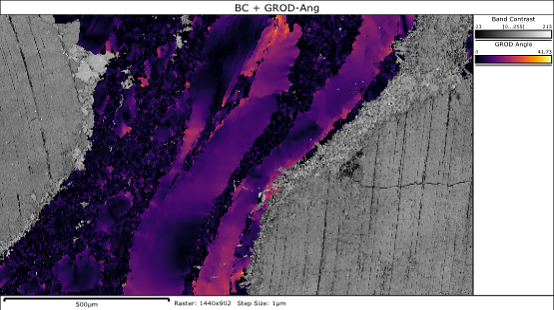

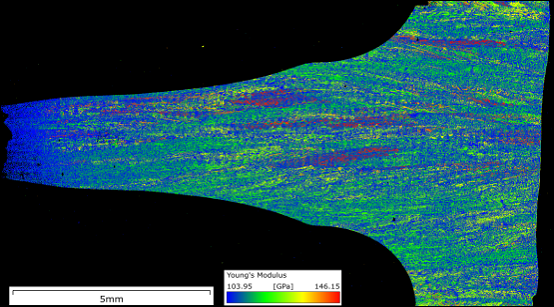

Strain Analysis tools

- Use the precision of MapSweeper to gain a complete picture of deformation within your material

- Plot Strain Tensor Maps

- Determine areas of pure Tension, Compression or pure Shear on your sample surface

Improved functionality for Particle Analysis

- More flexibility for manual manipulation of defined particles - join particles and sperate particles by manually defining a poly line

- Automated particle detection for quick subset creation

- Or manually subset individual particles for interrogation

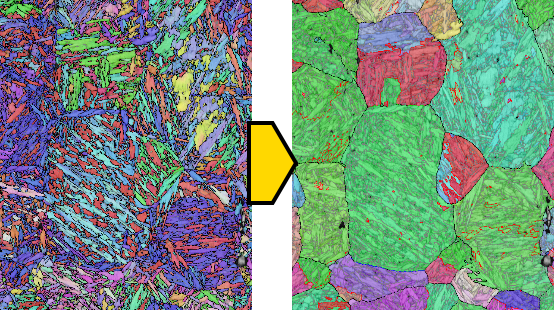

MapSweeper improvements

- MapSweeper is optimized for speed improvements (>5000pps indexing rate depending on GPU)

- Improved CIF import for more efficient simulations

- New refinement modes for Strain Analysis and Lattice Parameter (tetragonality) measurements

Powered by Bioz

Powered by Bioz