Products

FIB-SEM

Nanomanipulators

OmniProbeOmniProbe CryoSoftware

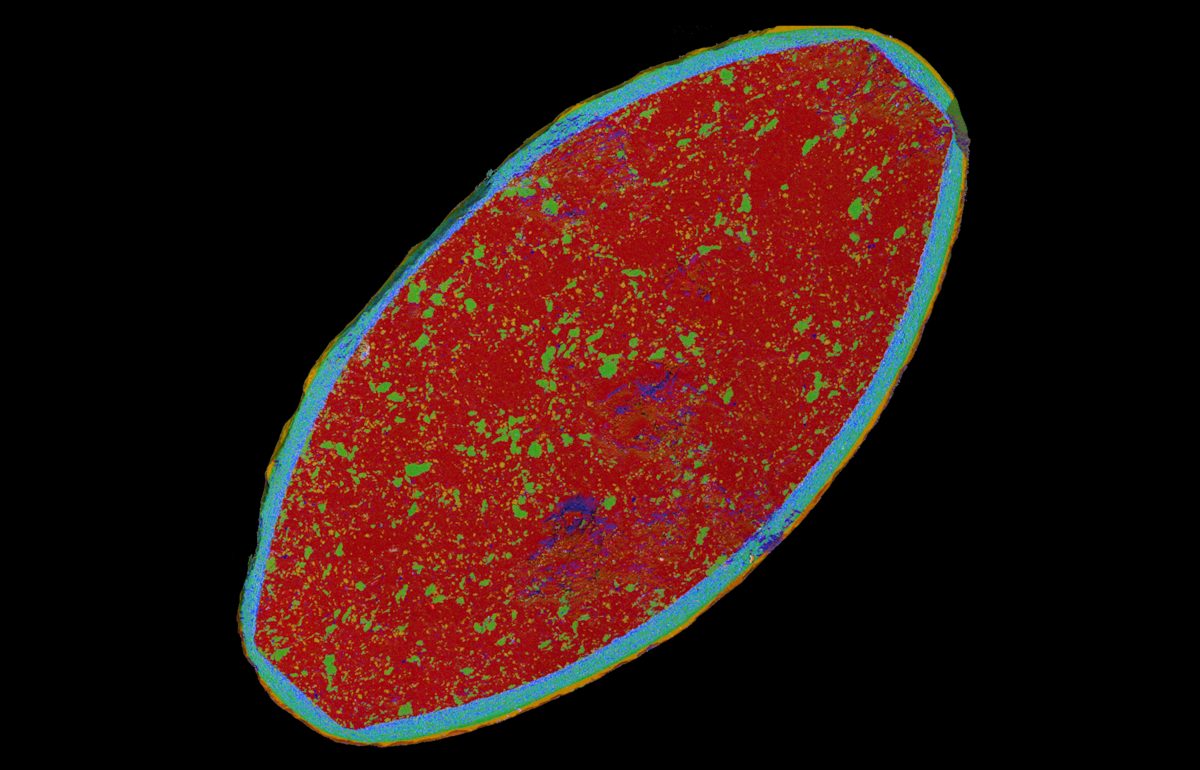

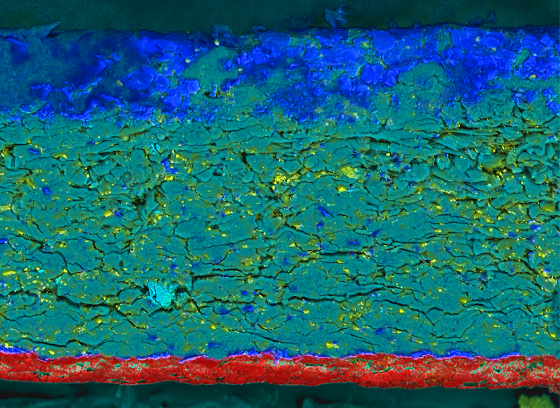

AZtec3DAZtecFeatureAZtec LayerProbeTEM

Hardware

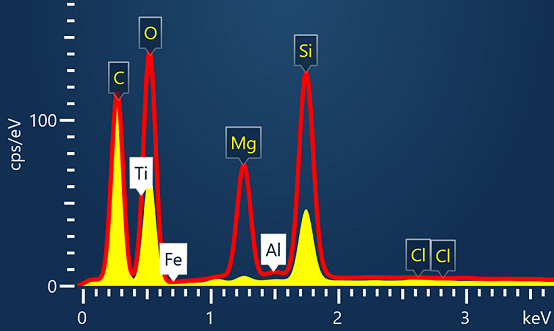

EDSUltim MaxXplore for TEMImaging

TEM CamerasSoftware

AZtecTEMRaman

RISE

Application Specific Software

Additive manufacturingAutomated mineralogyBattery materialsCorrelative microscopyFibre analysisGeological materialsGunshot residueHigh Temperature EDS analysisNon-metallic inclusionsParticle AnalysisPharma applicationsTechnical cleanlinessData Processing Software

AZtecFlexAZtecCrystalRelateSample Preparation

Ion Polisher