✔️ The highest sensitivity guaranteed

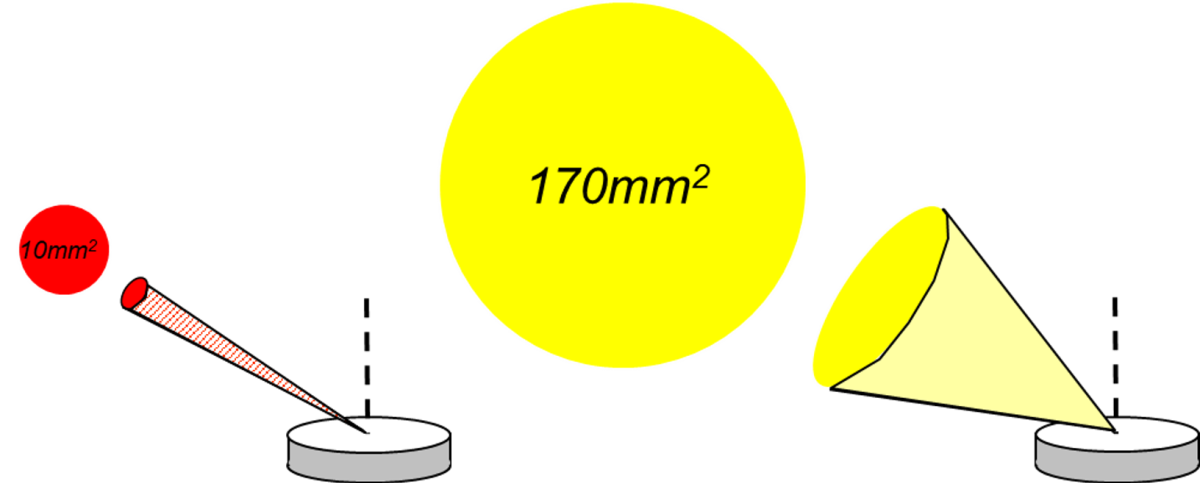

Sensor sizes from 40 mm2 up to 170 mm2 all offering the exact same analytical performance.

Ultim® Max ∞ (“Infinity”) SDD detectors unlock the infinite potential of EDS for characterising materials in the SEM. They combine unparalleled accuracy, sensitivity and speed to power AZtec Live software to solve the most complex or difficult analysis challenges.

Infinity means guaranteed performance, tested on installation, beyond the typical specifications of any other detector including the highest sensitivity guaranteed with sensor sizes from 40 mm2 up to 170 mm2 all offering the exact same analytical performance.

Ultim Max Infinity unlocks infinite potential for solving even the most complex micro- and nano-characterisation challenges. Whether your challenge is understanding the smallest nano-structures, measuring phase composition, identifying minor or trace elements, mapping compositional variation, or measuring features as quickly as possible, Infinity provides the right data to allow AZtecLive to give you the right answer.

Infinity represents the current state of the art in EDS detector technology providing levels and performance and capability that are unique, and critical to characterising the infinite range of samples seen in today’s FE- and FIB-SEMs.

Sensor sizes from 40 mm2 up to 170 mm2 all offering the exact same analytical performance.

Resolution guaranteed at CKa of 46eV or better at all count rates up to 50,000 cps.

Resolution guaranteed at MnKa of 127 eV or better at all count rates up to 200,000 cps.

Unique new Tru-Q® IQ spectrum processing. Each detector is characterised on SEM during manufacturing and individually optimised to ensure accurate data processing every time.

Infinity pulse processing and pile-up correction combine to identify elements and display real artefact-free element distribution.

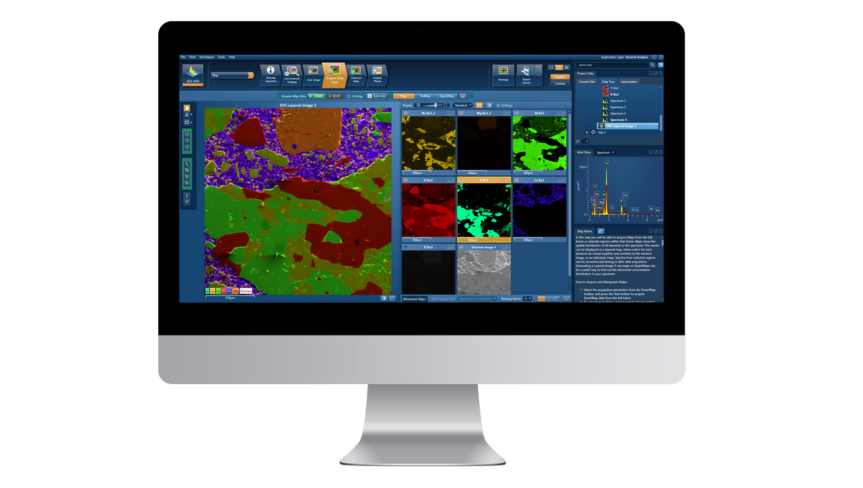

Using Ultim Max Infinity brings new capability to the SEM. Like other detectors Infinity enables element identification, quantitative analysis and X-ray mapping. Infinity offers so much more by combining all these capabilities together into live, real-time acquisition we call Live Chemical Imaging (LCI).

Live chemical imaging combines the outputs from the SEM’s electron detectors with Infinity EDS to provide an unmatched level of information and detail. Live electron imaging is well accepted and no user these days expects anything other than detailed morphological and material contrast information as they investigate their samples. With LCI a whole new layer of information is added with element distribution added as separate X-ray maps or a combined map and electron image.

No longer does sample investigation have to stop and wait when you want to determine the elements in your sample and where they are located, LCI displays this all the time.

Live chemical imaging workflows put SEM and EDS control into one powerful interface, enabling image optimisation (e.g. focussing, stigmation), magnification, stage control, image selection, and even spectra collection from a phase of interest, to be under the control of the user … all together. See what new information LCI and Infinity can reveal in your samples.

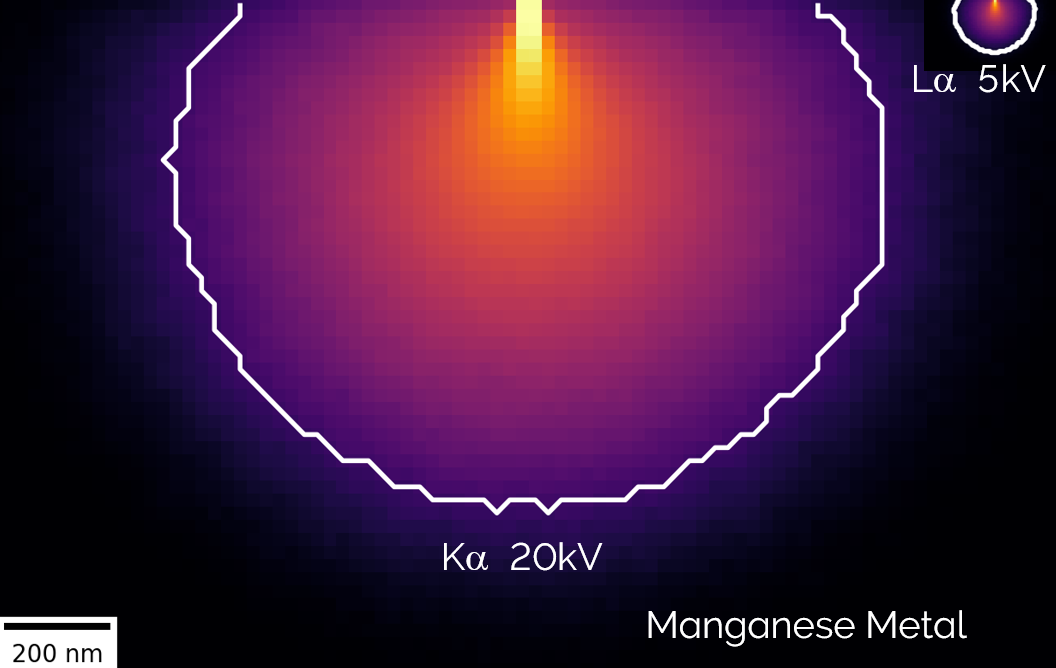

X-ray count rates from very small nano-structures are always very low. Reducing accelerating voltage from 20 kV (Microanalysis) to 5 kV (Nanoanalysis), increases spatial resolution for EDS by 10x to around 100 nm. However, that comes with a drop in count rate of typically around 750%.

Image shows the X-ray generation region at 20 kV and 5 kV. By reducing the beam energy from 20 kV to 5 kV the spatial resolution of EDS is improved to around 100 nm

Large sensors collect more X-rays and Ultim Max Infinity offers larger sensors, with sizes ranging from 40 mm2 right up to 170 mm2. Infinity makes up for the loss of count rate at lower kV, allowing smaller beam voltages to be used for even better spatial resolution and for the characterisation of even smaller structures.

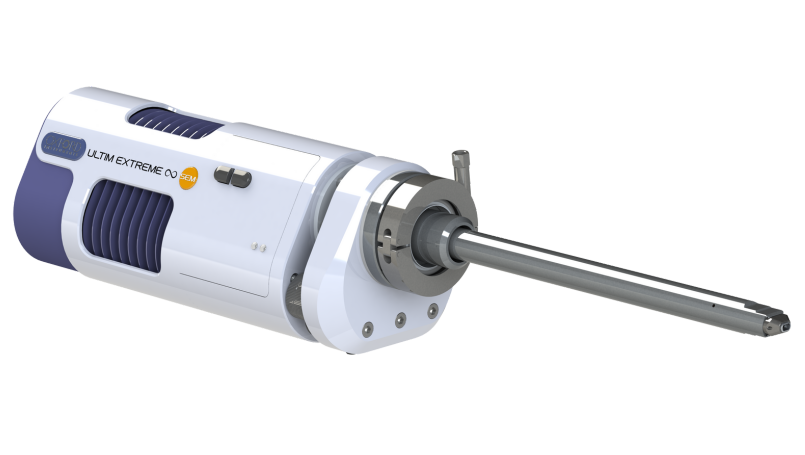

For the smallest nano-structures or surface science type surface sensitivity check out our windowless detector Ultim Extreme Infinity that makes sub-10 nm spatial resolution and sub-2 kV analysis a reality.

Not only is Ultim Max Infinity the only detector that offers the same guaranteed detector performance for every sensor size, but it is also the only detector specified for nanoanalysis, and the one with the highest count rate performance for microanalysis.

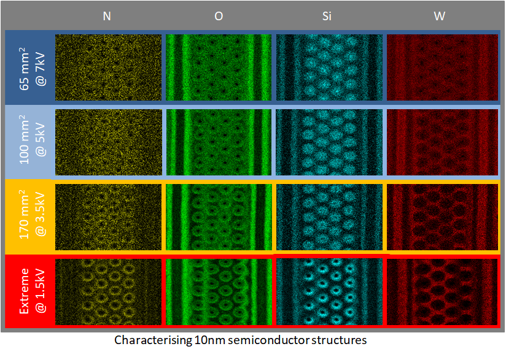

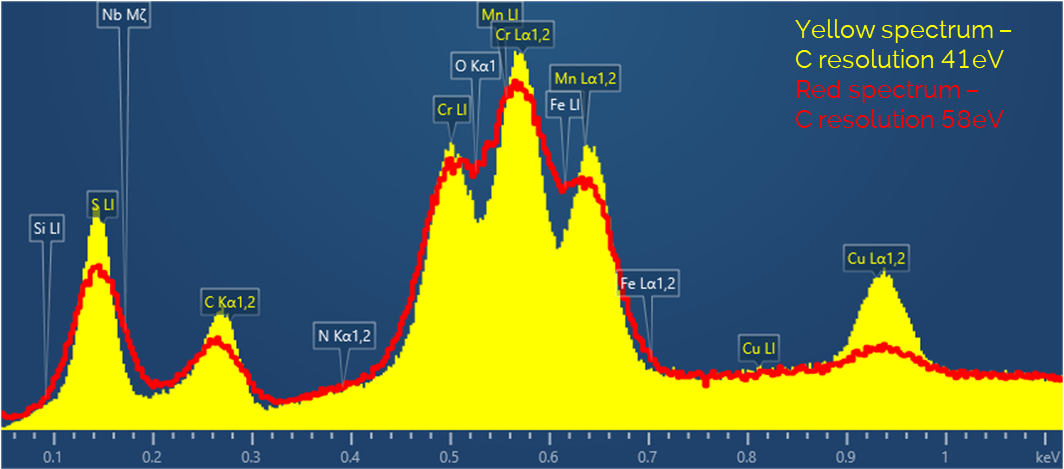

Forget Mn resolution, if nanoanalysis is your requirement, you’re unlikely to be using the beam conditions required to even see MnK X-rays, what you need is a detector with performance measured at the energy of X-rays you will be analysing and that means carbon resolution. Afterall resolution is actually much more important at lower energies because X-ray lines are typically around 5-10x closer together. Ultim Max Infinity has CK resolution guaranteed to be 46 eV or less up to 50,000 cps for EVERY sensor size all the way up to 170 mm2. That’s crucial as larger sensors have the sensitivity for nano-characterisation but still need excellent low energy detector resolution to perform the analysis successfully.

At low energy peak overlaps are common and complex, spectral resolution is key to processing this data correctly

At higher energy for Microanalysis, peaks are much more widely spaced, and performance is limited more by count rate. Ultim Max Infinity is unique in that it can achieve best performance (127 eV @ MnK) all the way up to 200,000 cps, again even for its largest 170 mm2 detector, and with large area detectors, high count rates like this are also easier to achieve.

Most detectors on the market these days claim compliance to ISO15632. Well, if that’s really the case then they have to have guaranteed performance at CK, FK and MnK and guaranteed resolution performance at all these energies at least up to 50,000 cps. Does yours? All Ultim Max Infinity detectors, whether 40 mm2, 65 mm2, 100 mm2 or 170 mm2 have the same guaranteed performance, tested on installation

46 eV or better at CK up to 50,000 cps

59 eV or better at FK up to 50,000 cps

127 eV or better at MnK up to 200,000 cps

Find out more about ISO15632 and why it matters by reading this blog: ISO15632 22 years on. What progress have we made specifying EDS detectors?

Tru-Q® technology revolutionised EDS when introduced with AZtec Energy all the way back in 2011. Using a fundamental EDS detector calibration measured with a synchrotron, enabled accurate characterisation of each detector type on a SEM. Using this characterisation Tru-Q powered new levels of accuracy and reliability in quantitative analysis, AutoID, peak deconvolution and real-time map correction.

Find out how Tru-Q revolutionised standardless quantitative analysis by watching our webinar: Quantitative EDS Explained: How to achieve great results

Tru-Q IQ takes things to the next level where each and every Ultim Max Infinity detector is characterised on a SEM during manufacture and then given its own unique detector optimisation. This optimisation is then confirmed during installation on your SEM. This gives unparalleled performance with every Infinity detector able to characterise accurately the most complex analysis challenges, solve challenging low energy peak overlaps and find smaller concentrations of elements.

The perfect fit to the spectrum data provided by Tru-Q IQ means minor elements like phosphorus can be identified under a complex overlap of NbL and MoL lines.

A perfect match of detector characterisation to output is essential when using the lowest energy X-ray lines for mapping. Lines with energies less than 500 eV allow lower kV to be used to optimise spatial resolution and characterise structures less than 50 nm in size.

For example, SL (149 eV), NbM (172 eV) and MoM (193 eV) lines all have energy lower than CK and are separated by just 23 and 21 eV. With Tru-Q IQ, accurate processing of these lines allows accelerating voltages of less than 3 kV to be used, and can reveal the true distribution of elements in phases as small as 30 nm.

EDS systems with large sensors can easily collect data from micro-structures at 20 kV at rates up to 1 million cps. This allows high fidelity X-ray maps to be collected in seconds. This is particularly useful to characterise elements present at minor (<5wt%) concentration due to their low signal to noise. The challenge however is that low intensity signals from elements like these are often swamped by other artefact signals, in particular:

Pulse pile-up occurs when two X-rays arrive in the detector so close together they are measured as one event with the sum of their energy. When input count rates climb through the many 100s of thousands through 1,000,000 cps, pile-up artefacts can start to dominate the signal, obscuring real information, and potentially reducing the signal from real X-ray peaks. In its worst case, at the highest throughputs, the actual count rate of the X-ray peaks starts to drop.

Infinity has solved the pulse pile-up challenge to offer high count rate X-ray mapping where real element peak counts are maximised and artefacts are eliminated. Infinity uses a new approach to signal processing that maximises peak count rate rather than total count rate, by supressing the pile-up signal.

At the highest count rates pile-up artefacts are minimised to a level where they can be corrected by a pile-up correction method, which is individually optimised for each detector using Tru-Q IQ technology. For the first time sum spectra, used to automatically identify the elements in the map, can also be corrected using a new phase clustering approach, revealing elements and minor phases that are easily missed.

The speed of the pile-up correction algorithm is also now fast enough to correct pixel by pixel during Quantmap processing. This means that an X-ray map dataset can now be rapidly changed from raw data to real element distribution correcting for peak overlaps, X-ray background, matrix effects such as X-ray absorption and now the removal of interferences due to sum peaks. The results can be incredible, revealing new levels of detail and allowing the mapping of very low element concentrations in minutes.

For challenges beyond conventional EDS in the SEM, such as for the characterisation of nano-structures less than 25nm in size, for looking at the thinnest surface layers, or simply when the accelerating voltage is too low and the working distance too small, to see an EDS signal, Extreme Infinity provides the solution. Optimised to work at the lowest beam energies and the shortest working distances, with the best low energy spectral resolution.

Find out more

AZtecLive is the software that when powered by Ultim Max Infinity brings the infinite potential of EDS to life. See how live chemical imaging is a new approach to sample investigation and understand our workflows for qualitative and quantitative analysis as well as X-ray mapping and linescanning. Discover the tools that can help you use EDS to solve your characterisation challenges in the SEM.

Find out more

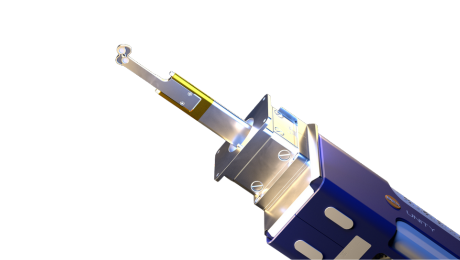

Unity is a new detector for a revolutionary new imaging technique in the Scanning Electron Microscope (SEM). Unity is the world’s first Backscattered Electron and X-ray (BEX) Imaging detector. It seamlessly combines backscattered electron and X-ray signals to deliver rapid high-definition colour images embedded with elemental data as you navigate around your sample.

Find out more