Particle & Feature Analysis with AZtecFeature

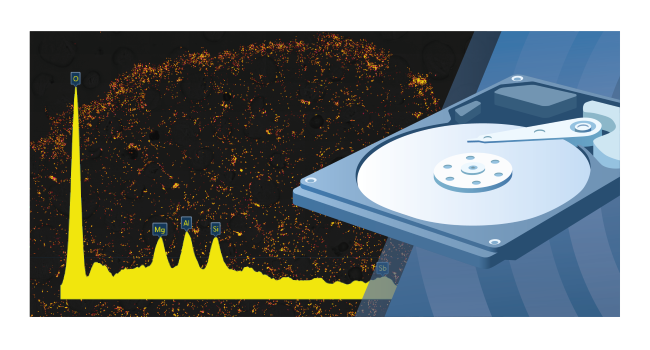

Here we consider AZtecFeature in the context of engine wear monitoring, geology and air cleanliness and pollution. We discuss how key improvements in AZtecFeature in combination with recent advances in EDS detector hardware make it a compelling proposition for a much wider group of researchers and practitioners in industry and academia.