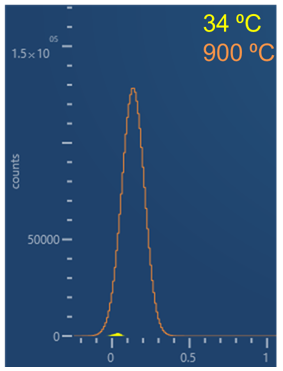

Comparison between a spectrum acquired at 34°C and 900°C. The background low energy noise has increased by two orders of magnitude.

How do we combat these effects?

To continue collecting accurate data even when the detector is being flooded with visible and IR radiation, there needs to be a high processing power to allow extremely high throughput embedding the retrospectively low X-ray counts from a sample into the low energy noise.

The combination of our extreme electronics with AZtecTEM Live opens the door to a new range of dynamic experiments. This is generated by both the ability to collect and analyse data at much higher temperatures and the ability to observe chemical changes as they occur.

High-temperature EDS

With the ability to heat a sample to temperatures greater than 1000°C within a TEM, it is essential that we maintain our ability to acquire EDS data and that the data acquired can still be analysed accurately. See below the analysis of Au nanoparticles heated to 1000°C within both a JEOL-F200 and a JEOL ARM-200F. At this temperature, we maintain full mapping capabilities, auto-id and quantification functionality despite the noise levels associated with high temperatures.

Heating of Au nanoparticles on a SiN membrane mounted onto a MEMs based heating chip. The Au can be seen agglomerating into nanoislands.

Live chemical changes

The purpose of a heating holder is to stimulate a dynamic environment around a sample and to observe any changes that occur. The changes themselves can be dynamic and therefore here one second and gone another. This has always been a limitation in the reliability of findings as there was no way to observe these changes as they happened – the experiment must be paused, analysed and then continued. AZtecTEM Live has provided the potential to acquire continuous EDS maps and spectra in real time. An example of such is the observation of Cu precipitation within an Al2Cu alloy, acquired on a JEOL ARM-200F. In this experiment, Cu precipitates out of the alloy at ≈ 300°C before annealing back into solution at 450°C. Both the Cu precipitation and subsequent annealing are observed in live time with no need to stop the experiment.

Cu precipitation and subsequent annealing from an Al2Cu alloy heated continuously from 0 – 450°C.

Heating can present many challenges for EDS analysis, view our recent webinar to understand more about the limitations of heating, other in situ experiments and how we work to overcome them.