When I consider all of the technological developments that have improved the EBSD technique over the past 30 years, it amazes me that we are still using the same basic approach to EBSD pattern analysis that was first proposed by Niels Krieger Lassen back in 1992 – namely the Hough transform. The Hough transform is a very elegant image transform that is used to detect linear features in images (such as Kikuchi bands in EBSD patterns), and it has served us very well: it is fast, it is extremely robust, it copes well with noisy patterns, and it can be used with all sorts of different collection geometries. It is not a surprise that all commercial EBSD systems, including our AZtecHKL software, use pattern analysis routines based on the Hough transform (or the closely related Radon transform). But is the era of the Hough transform coming to an end?One of the best parts of my job as an EBSD product manager is when I am involved in the development of a new product that really can make a big difference to our customers. Our latest tool in AZtecCrystal (our EBSD data processing software) is one such example: AZtecCrystal MapSweeper.

A new approach to pattern matching

MapSweeper is our first venture into the world of EBSD pattern matching technology - an alternative approach to the interrogation of diffraction patterns that compares experimental to simulated EBSD patterns. Many aspects of this development are not new: realistic “dynamical” simulations of EBSD patterns have been available for over 15 years (Winkelmann et al., Ultramicroscopy 107 (2007)), and the first indexing approach using simulated patterns was proposed in 2015 (“Dictionary Indexing” – Chen et al., Microscopy and Microanalysis 21). What is new, however, is the way in which we have implemented the use of simulated patterns.

Although existing techniques have demonstrated the enormous potential of pattern matching techniques (especially for the analysis of very challenging samples that give poor quality EBSD patterns) they have generally been very slow techniques that either require extensive and time-consuming set up for each dataset analysis, or navigation through an array of complex mathematical functions to enable more rapid image correlation.

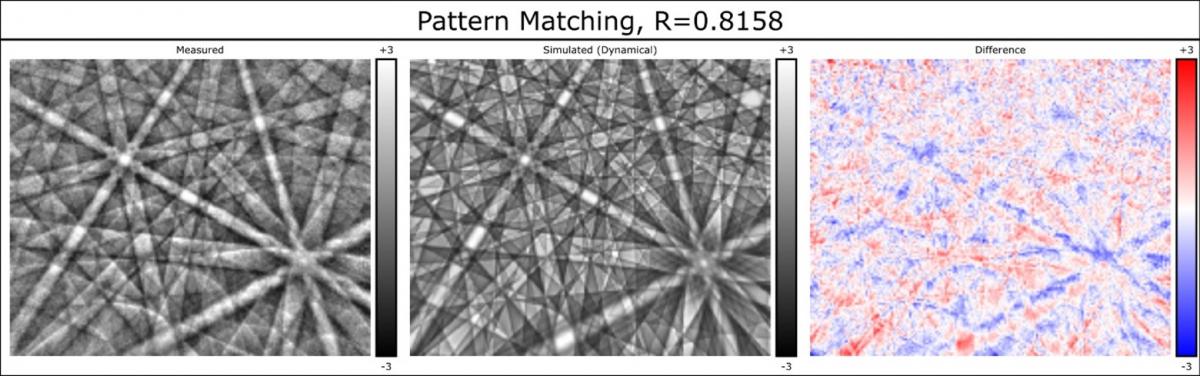

Pattern Matching example from Copper (exported directly from AZtecCrystal MapSweeper). Left – an experimental EBSD pattern, centre – the equivalent dynamically simulated pattern (with refined orientation and calibration), right – the difference between the 2 patterns. Note the exceptional match between the simulation and the real-life pattern (the “R” value is the normalised cross correlation coefficient).

Pattern matching made simple

MapSweeper, on the other hand, is beautifully simple. It is based around the fundamental requirement that we want it to work on any sample type with minimal set up and, wherever possible, to utilise any pre-existing data that has been collected using the conventional Hough-based indexing at the microscope. After all, after 30 years of development, the Hough transform indexing is highly optimised and provides valid information from all but the most challenging of samples.

This “hybrid” method makes the pattern matching process much faster (since we already have a starting point of the orientation and phase determination, speeds over 1000 Hz are possible) and enables us to start extracting enhanced data from our samples, whether that be improved orientation precision (to better than 0.01°), resolving complex pseudosymmetries, reliably discriminating between similar phases or determining crystal polarities.

In those cases where indexing using conventional Hough-based methods really does not work, we can still switch to a more “brute force” approach using a newly developed method that we are calling “dynamic template matching” (DTM). Unlike dictionary indexing, DTM calculates everything on the fly for each point in the dataset. This means no extensive pre-calculations are needed, there are no issues with multiple phases, and the approach works well with low magnification data (since it takes the geometry calibration for every point), unlike other methods. In short, DTM works with any type of dataset without any difficulties.

Now you might think that calculating everything on the fly would be very slow, but the beauty of the method is that it can be run using very low resolution (binned) EBSPs and then coupled with a higher resolution refinement step to deliver excellent angular precision. This combination can work at speeds of 100-200 Hz (depending on the crystal system and the PC specification) and results in significantly higher precision data than conventional Hough indexing.

Astonishing results, with broad application

So, what applications benefit from this new approach? Well, that’s the fun part. Over the past 5 months, during extensive testing, I have applied MapSweeper to datasets from nanomaterials (nanoparticles as well as nanostructured films), oxide scales in steels, microelectronic solder bumps, solar cells, complex metamorphic rocks, fossils, battery cathodes, wide band gap semiconductors and a range of highly-deformed rocks, metals and alloys. The results have been astonishing; enabling us to characterise individual dislocations, resolve subtle pseudosymmetry-related errors, increase the effective resolution in transmission Kikuchi diffraction analyses and so on – basically, to enhance each and every dataset.

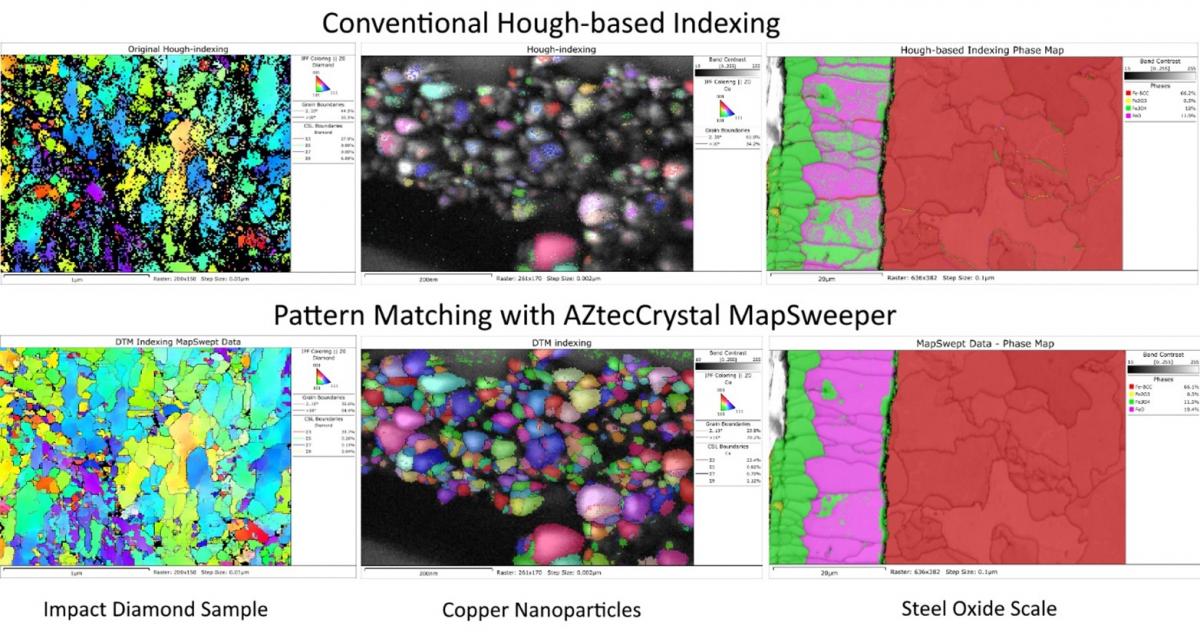

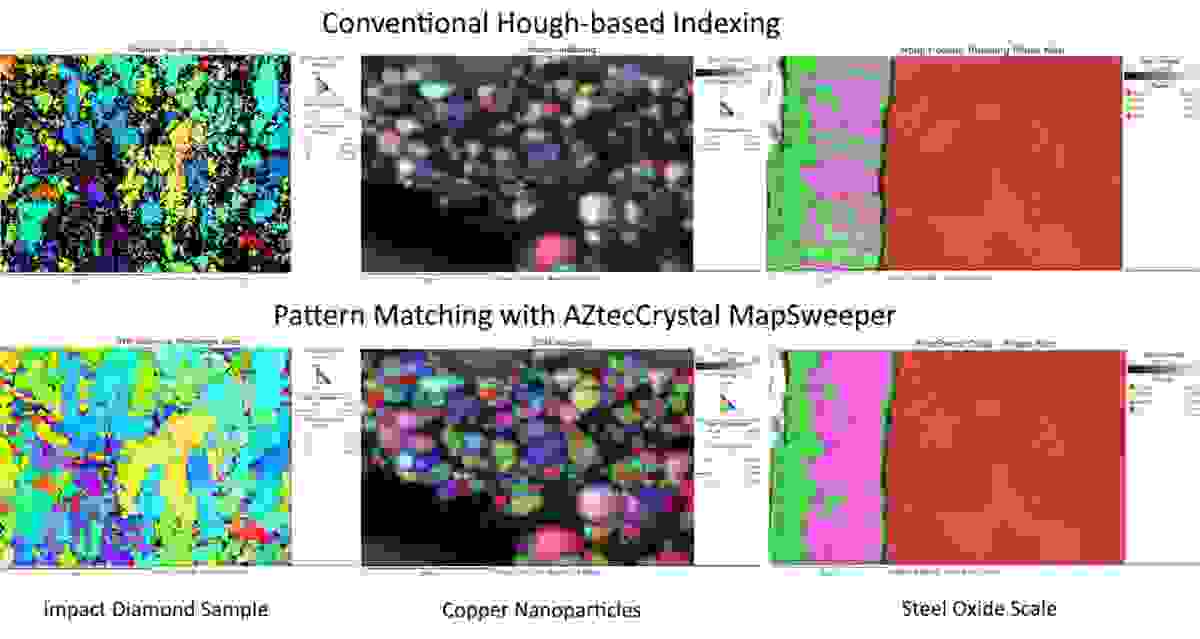

Examples of the application of AZtecCrystal MapSweeper. Top Row – results using conventional Hough-based indexing. Bottom Row – Enhanced data following reprocessing with MapSweeper. Impact diamond data courtesy of Prof. Sandra Piazolo, University of Leeds, UK.

Join me to learn more

A few examples are provided in the image, but to find out more about this exciting development, I would encourage you to sign up to an upcoming webinar in which we’ll look specifically at how MapSweeper can be used across a range of semiconductor and microelectronic packaging applications, including to resolve crystal polarity, reliably identify intermetallic phases and to characterise dislocation populations. You can find out more and register for the webinar here.

So, to return to my earlier question – is the era of the Hough transform coming to an end? Well, not quite, but for the first time since I started working with EBSD almost 30 years ago, the Hough transform has certainly got a battle on its hands.