![]()

Laser Printing for Advanced Manufacturing

Superalloys such as niobium modified nickel Alloy 718 have excellent high temperature performance and environmental survivability. This makes them ideal for applications such as turbine blades, nuclear plants. The performance is a result of Gamma double prime and gamma prime precipitates. The precipitates are present in the alloy regardless of fabrication process. However the microchemistry, morphology, metrology and distribution vary due to the fabrication.

These excellent properties however make it difficult to machines and an ideal candidate for ALM process. The process of laser printing means molten metal is cooled on a cold surface; this rapid cooling results in long column textured grains at the start of a component. The size and texture of the cooling zone can be determined with EBSD.

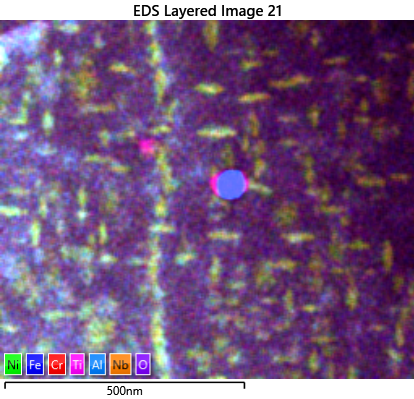

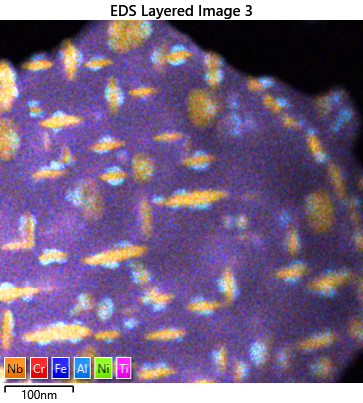

To understand the integrity of a printed part, the formed precipitate structure must be characterised. This requires a number of complementary techniques. The size of the gamma double prime and gamma prime precipitates means they are not suitable for conventional EDS, however the use of low KeV EDS in SEM can be used. To full characterise the microchemistry of the precipitates TEM EDS is required.

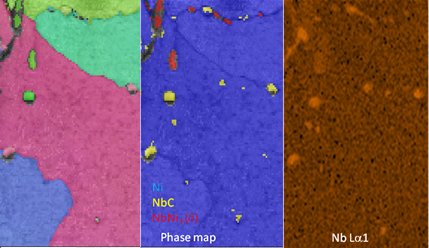

Other phases can form in the printing process, such as niobium carbides and nickel niobium. Both phases are niobium rich and have similar crystal structures making them difficult to distinguish by EBSD or EDS alone, the use of simultaneous EDS and EBSD enables them to be differentiated.

Other phases can form in the printing process, such as niobium carbides and nickel niobium. Both phases are niobium rich and have similar crystal structures making them difficult to distinguish by EBSD or EDS alone, the use of simultaneous EDS and EBSD enables them to be differentiated.

Back to Advanced Manufacturing

Back to Advanced Manufacturing