Metal 3D Printing

The bonding process which occurs in powder based additive manufacturing is not always well understood. The nature of ALM means that the process of bonding is occurring in 3-dimensions, to understand this requires analysis in 3D. The ability to understand the process.

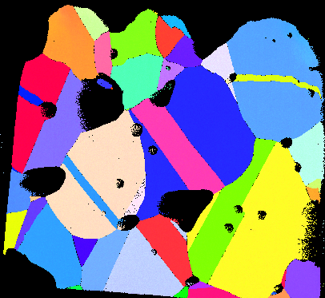

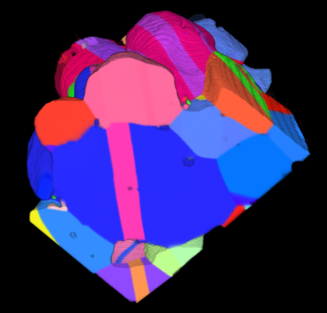

A copper powder was bonded by pressureless sintering. To understand the densification of the powder, grain evolution and how the microstructure of different powder particles interact, the produced metal microstructure was characterised by EBSD in 3D. This shows the growth of grains in one powder particle into another, void locations and if any texture evolves during the process.

3D reconstruction of pressureless sintered copper, shows how the microstructure of separate powder particles bond to form a single piece

Image courtesy of Tim Burnett - University of Manchester

FREE WEBINAR

In our upcoming webinar, you can learn:

- The challenges associated with in-situ heating experiments for EBSD and how to overcome them

- The effect heating-rate has on the high-temperature recrystallisation mechanism in Ti

- Possible links between twinning and the recrystallisation mechanism in the grain growth of high temperature Ti

- How fast and sensitive CMOS EBSD allows the effect of cooling rates on the nucleation of the room temperature phase to be measured, and how this is related to the high-temperature microstructure

back to Advanced Manufacturing