4th November 2020 | Author: Dr Simon Burgess

Be Confident in your EDS Results and Maximise your Productivity

EDS technology is developing ever more rapidly, with new hardware and software promising ever more sensitive and high-speed analysis.

This leads to a common question about the best parameters to use for acquisition and what conditions should be used to ensure accurate analysis. There is no right answer to this question as it depends on many factors, however, it's really easy to find out yourself and I always recommend this. All you need is a sample with the type of materials you want to analyse. A sample of known composition is best, but even if you are not sure of the composition you can use it to check what range of conditions you can use without affecting the results.

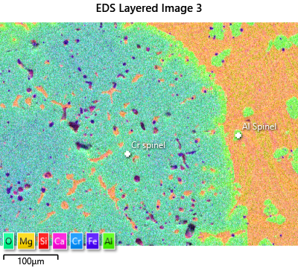

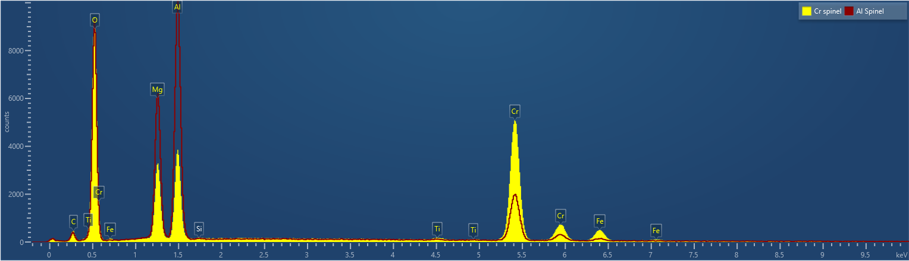

I often use a slag sample which contains large numbers of spinels of varying composition. Spinels are great because their composition is predictable. They have the formula AB2X4, where A are divalent cations (e.g. Iron, Magnesium, Manganese and Zinc), B are trivalent cations (e.g. Chromium and Aluminium) and X is oxygen. This means that in atomic % Oxygen should be 57.1%, Mg+Fe 14.3% and Al+Cr 28.6%. With this information I can take this sample to any system and check its ability to accurately analyse this type of material, giving me high confidence for the analysis of minerals, ceramics, steel inclusions etc.

Normally I start at relatively low count rate to check the system is working well. This means long process time and 20kV accelerating voltage. With the latest large area detector this still means throughputs of over 50,000cps, at beam currents of less than 1nA, and an acquisition time of about 10 seconds. Below is a typical standardless result collected under these conditions for two of the common spinels in this sample.