11th November 2020 | Author: Dr Sam Marks

How to reduce carbon contamination when working at low kV

In this blog, I will look at the formation of carbon contamination when performing low kV EDS and what can be done to reduce it.

Carbon Contamination – What is that black mark on my sample and how do I remove it?

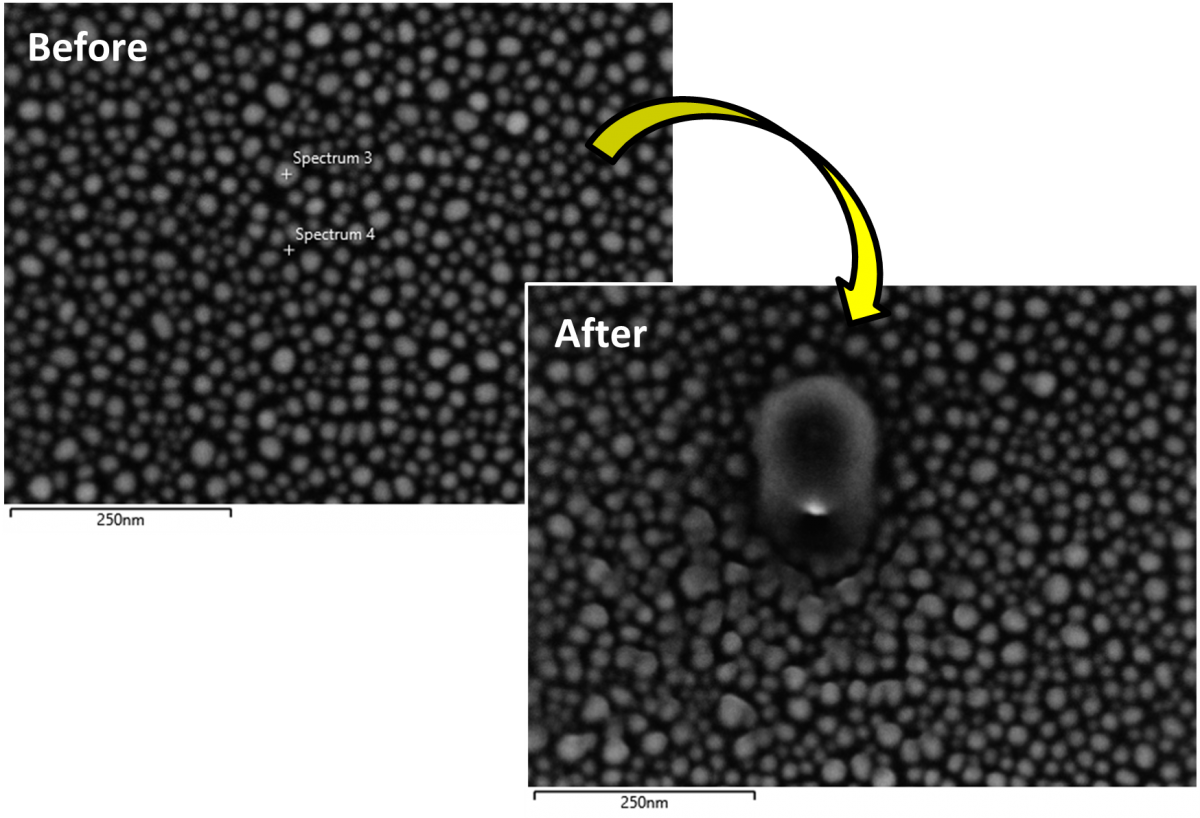

We often receive images from customers, like the one shown below, of a skilfully prepared SEM sample covered in dark areas of contamination following EDS analysis.

Sn balls examined using Point and ID analysis in the SEM. The 2 experimental points are highlighted on the before image with the after image showing the resultant formation of surface contaminants.

What is being observed is the deposition of carbon on the surface of the sample from hydrocarbon-based contaminants. As the electron beam passes over the hydrocarbons, they dissociate forming a nanoscale carbon paste. This is an issue that becomes more prominent at low accelerating voltages as the electron beam interaction becomes more focussed on the surface of the material with the resultant contamination negatively influencing the spectrum as C X-rays are generated. The sources of hydrocarbons are quite varied but are often put into 2 categories: dirty samples or dirty microscope.

The most robust method of removing contamination during SEM analysis is through plasma cleaning. A range of plasma cleaners are available, with most SEMs fitted with an in situ plasma cleaner developed to remove hydrocarbons from either the sample or the microscope chamber itself. If large amounts of contamination are being observed during EDS, then running the plasma cleaner for 30 minutes will often clear any hydrocarbons from the surface of the sample and reduce the amount of contamination observed. If contamination is observed, the experiment should be stopped, and the sample cleaned. There are also a broad range of ex situ decontamination techniques with the most common being plasma cleaning, UV cleaning, ion polishing and sample baking. Follow the recommended instructions for each device and if baking a sample, I would suggest starting at 80 °C and baking for 2-3 hours before imaging a sample, this also applies to TEM!

With in situ plasma cleaners offering convenience as they are attached to the SEM column. The different decontamination methods all have a range of pros and cons and it is not uncommon to use a combination of techniques to ensure a clean sample. Experiment with the methods available to you, to discover what works best for your material of interest.

Carbon contamination when working at low kV can create huge frustration. Hopefully, this blog has given you some helpful idea on how to combat contamination in your SEM and will allow you to get accurate and reliable results from your sample. Our Ultim Extreme detector can open new avenues of materials characterisation in fields such as life sciences, semiconductors, and batteries due to its unique capabilities. To discover exactly how the Ultim Extreme can aid you in your research, book a demo with one of our application specialists.

Book a Demo