The first rule of baking is that you must accurately weigh your ingredients if you want to make the perfect cake. As technology advances, we see this parallel applied to a range of unconventional baking methods, for example, 3D printing. This requires exact quantities of “ingredients” and a recipe that must be followed, varying external factors like temperature, pressure, or flow rates of gasses and liquids. When applied to the nanoscale, weighing ingredients becomes extremely challenging, with a 10 nm Pt nanoparticle estimated to contain approximately 20,000 Pt atoms which would weigh approximately 6.5x10-21 kg, far beyond the measurement capabilities of our kitchen scales.

One approach to weighing nanoparticles has been investigated by Oxford University, in which advanced TEM EDS quantification has been utilised to acquire the mass thickness value for a nanoparticle, which can then be used to estimate the number of atoms present within that nanoparticle.

The Ingredients

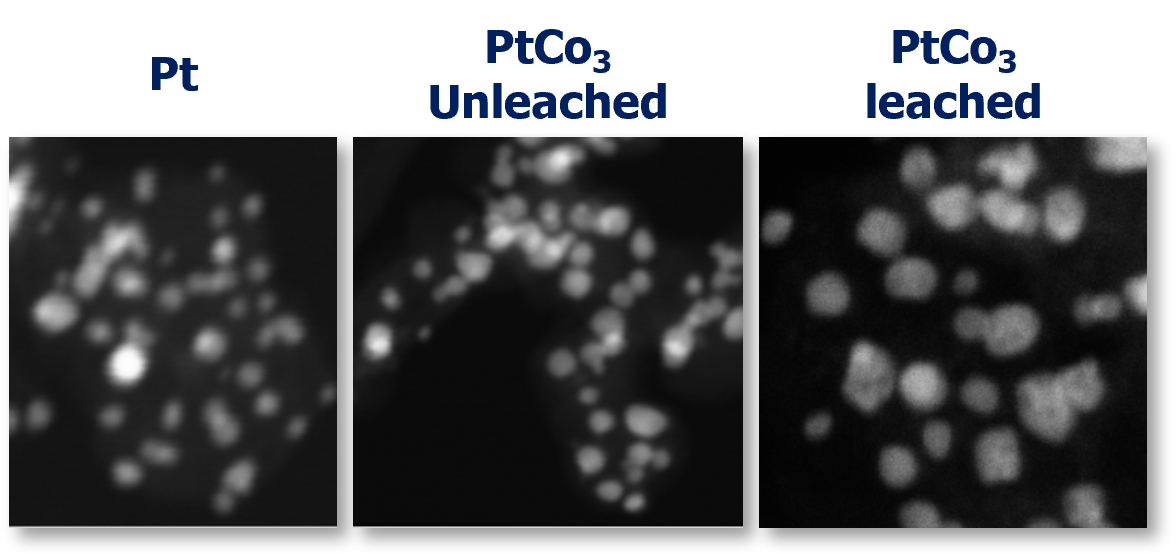

In their study, Oxford University examined 3 nanoparticle specimens: Pure Pt, PtCo3 (Unleached) and PtCo3 (Leached) - the leached specimen had been treated to remove a significant quantity of Co.

TEM images of the 3 nanoparticle samples dispersed on lacey carbon and imaged in a TEM, the nanoparticle diameters range between 3 and 15 nm.

The Recipe

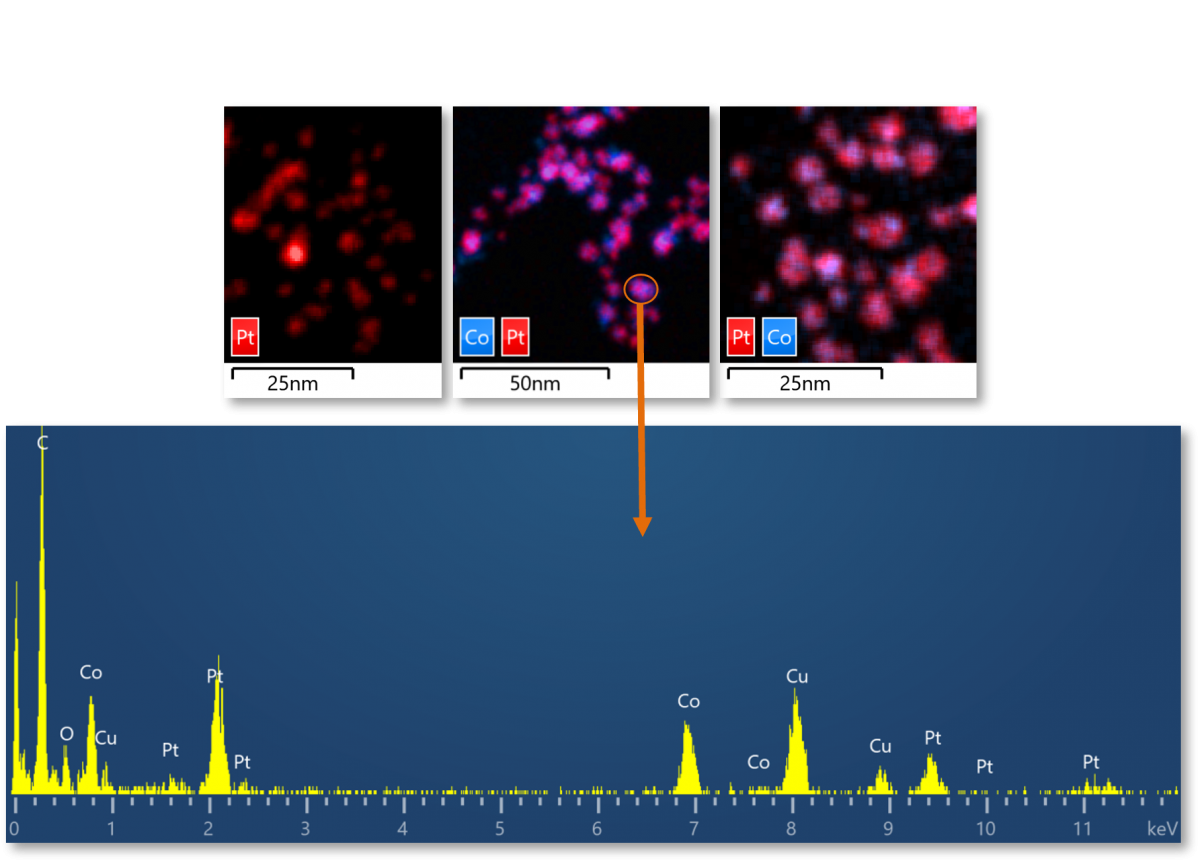

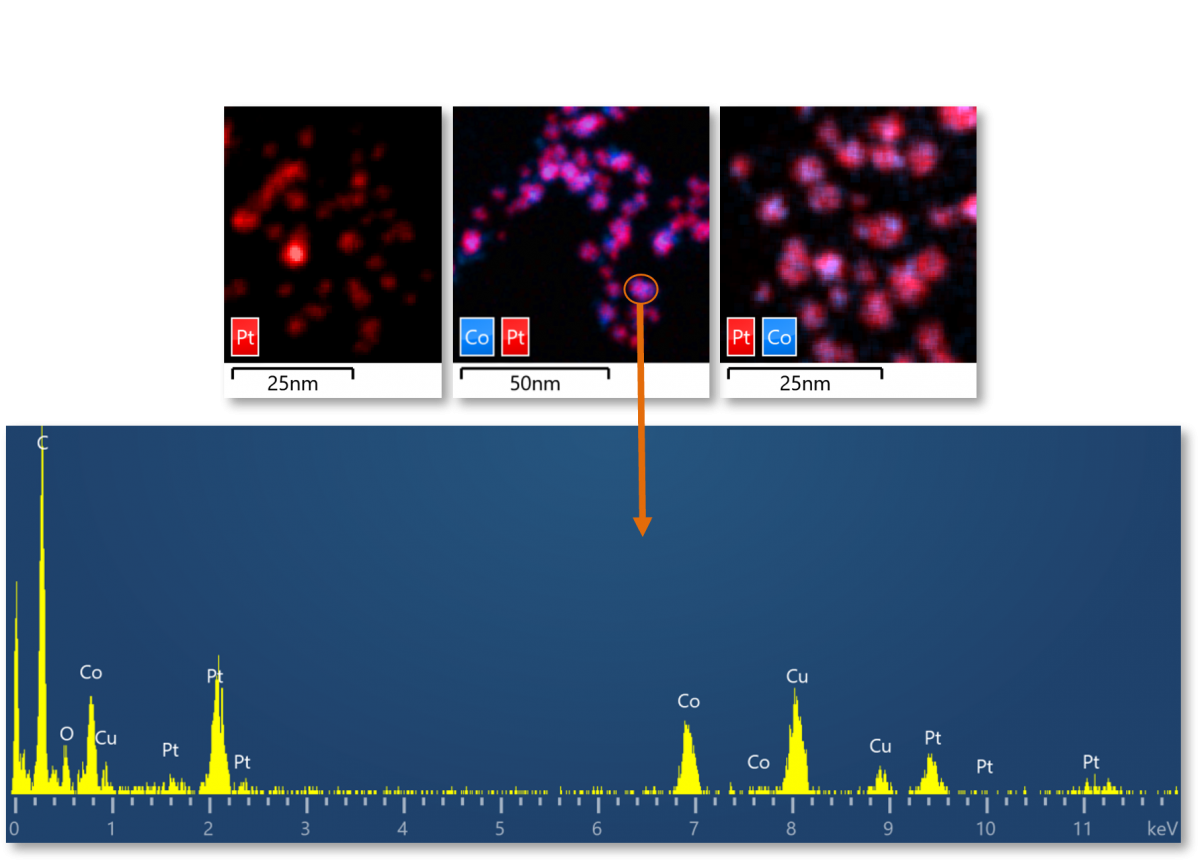

A number of EDS spectrum images were acquired for each specimen to visually map the distribution of Pt and Co within the nanoparticles. From the spectrum images, we can extract the EDS spectra for each nanoparticle and note the circular diameter of the particle. We can then apply the M2T quantitative routine, described below, to extract the mass thickness value, µ, for each particle.

Spectral images of the 3 samples, visualising the chemical distribution of Pt and Co within the nanoparticles. An example of an extracted spectrum is shown from the highlighted PtCo3

nanoparticle.

The Theory

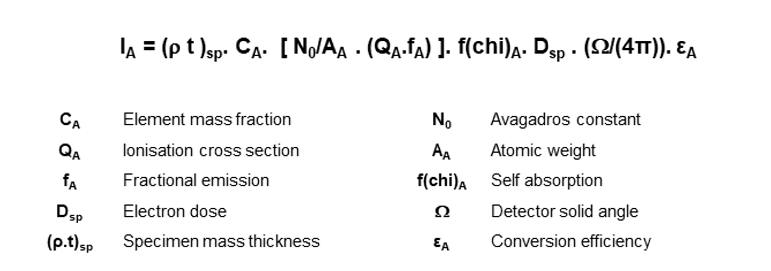

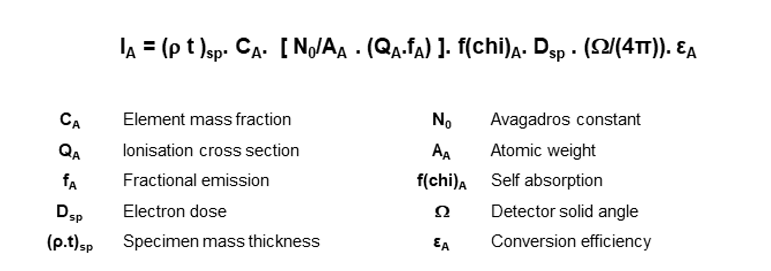

Accurate TEM quantification is extremely complicated, relying on a range of variables that can easily be overlooked when performing basic cliff-lorimer TEM quantification. For the analysis of thin specimens in a TEM, the X-ray intensity, IA, for the emission line of element A is given by:

The X-ray intensity is not only dependent on beam current (part of Dsp) and composition (CA), but also on density (ρ) and thickness (t) which govern the atoms per unit area in the direction of the electron beam.

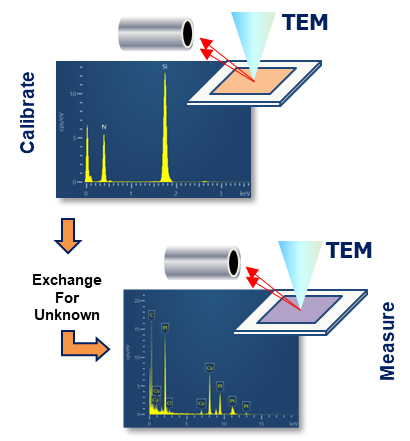

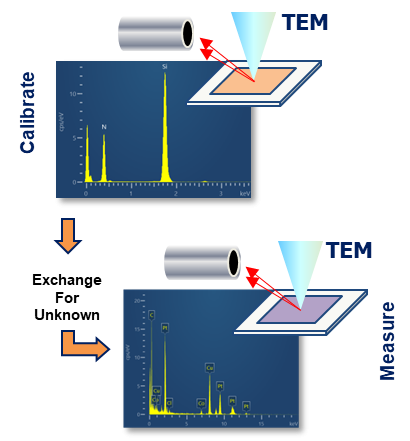

Therefore, in TEM, if the beam current is known, the mass thickness (pt) and relative elemental composition (CA, CB, etc.) can be obtained. We can calculate Dsp.(Ω/(4π)). εA by acquiring EDS data from a TEM standard under the same acquisition conditions, which is used to calibrate our quantification for the acquired beam current. From this mass thickness can then be directly extracted from an unknown sample.

Example of the M2T calibration routine required for advanced TEM quantification

The Results

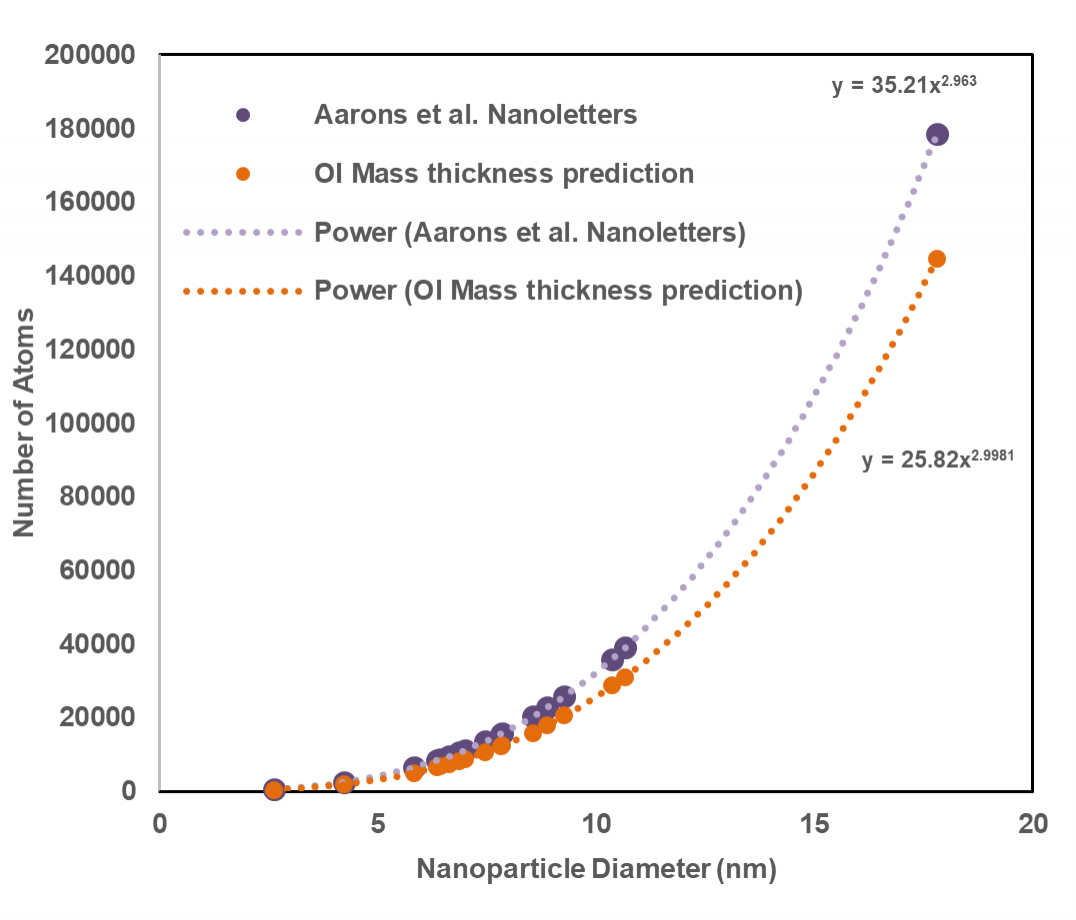

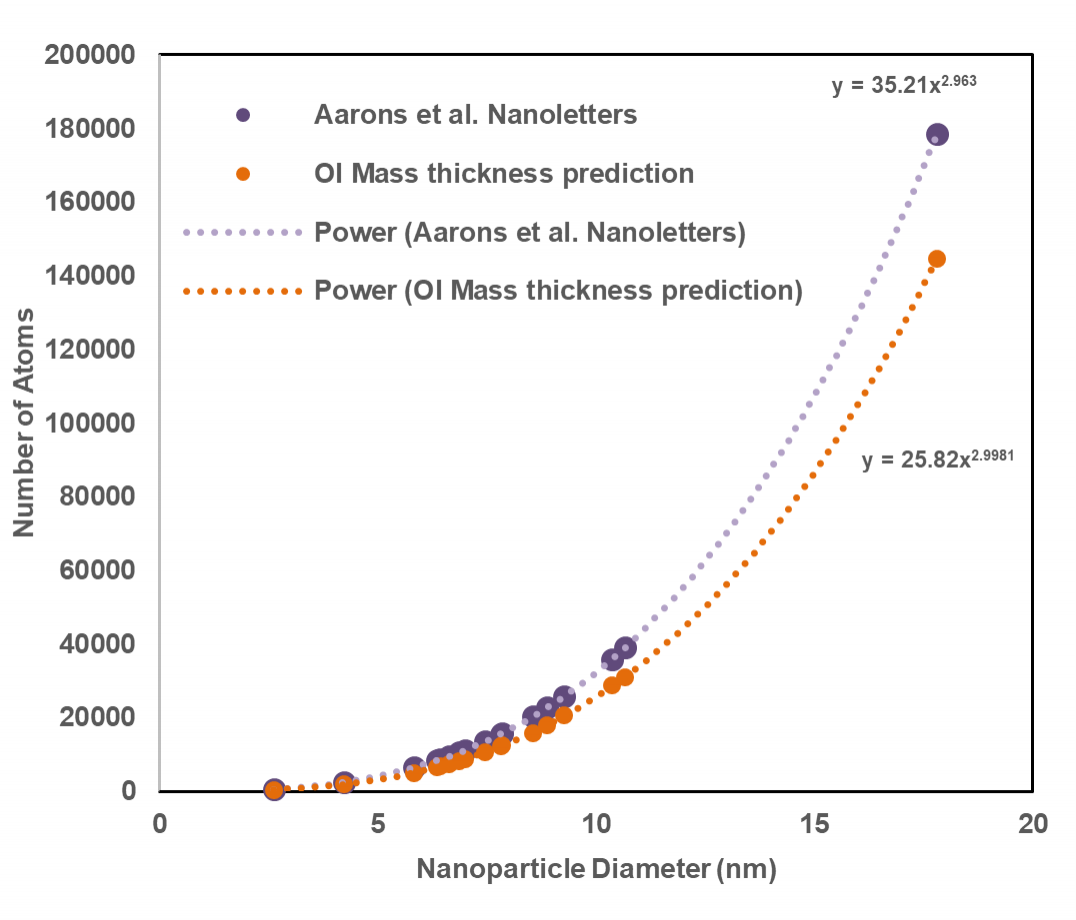

The composition of each nanoparticle was measured in terms of mass thickness, µg/cm3. This was then converted into atoms/nm3, and from that, the number of atoms in each particle was estimated with results compared to theoretical models developed by Aarons et al[1]. The results showed good agreement with the theoretical models for small nanoparticles, with some divergence from the theoretical calculations as the particle size increases. This suggests that this experimental method can successfully be applied to weigh nanoparticles.

[1] J. Aarons et al, Nano Letters, 17(7) (2017)

Experimentally calculated number of atoms for a range of nanoparticle diameters, comparing OI mass thickness data to theoretical modelled data.

The Future of Atomic Baking

Nanoparticles currently have a wide range of applications notably in catalysis, medical science, drug delivery and next generation electronics and solar cells. In these applications, there is a growing need to utilise a specific size range of nanoparticles to fulfil a task. Atomic weighing allows users to characterise nanoparticles to the level required to unlock more targeted applications.