16th December 2020 | Author: Dr John Lindsay

What makes a good nanomanipulator

While working in research and at Oxford Instruments, I have used many different FIB-SEM’s and manipulator combinations. On paper the systems were almost identical, but the reality as a user was very different. There were systems where you dreaded liftout because of the risk it posed to the sample you spent the last few hours creating, and others where liftout just worked. Here I will discuss a few of the different aspects which makes a good manipulator.

A common starting point when looking at a manipulator is the motor type. Most modern manipulators use piezoelectric motors, but there are multiple piezoelectric motor designs. OmniProbe manipulators’ unique design uses multiple synchronised piezoelectric elements. This design allows the manipulator to move smoothly and continuously across its full range of movement, without any jumps in motion which are commonly associated with slip-stick motors employed in some other manipulators. The motors are also capable of a large range of velocities. You may be interested to know that resulting from the ability to move continuously at all speeds, at its slowest speed an OmniProbe 400 would take just over 509 days (calculated, not tested) to complete a move across its full range on the Z axis. At its fastest setting this takes only a few seconds.

The second thing to look for on a manipulator is encoders. Encoders measure position, this positional information can be used to create stored potions. Stored positions allow the probe to be quickly and simply moved from a retracted position to ready for use, with a single click. This can be seen to the right. The use of the positioning information while the probe is moving (closed loop feedback) produces reliable velocity and step control.

OmniProbe moving from the retracted position to a stored position in the centre of the image

Other design parameters that set OmniProbes apart are that they are port mounted and designed for linear movement. Port mounted is important as it will not restrict sample size or interfere with other detectors. Being mounted on a port allows you to retract the OmniProbe out of the way without the need to remove from the microscope, as can be seen on the chamber scope above. Linear design is important as it makes the setup (calibration) of the manipulator more intuitive, and means when the probe retracts it moves straight out the chamber without risk of colliding with other detectors.

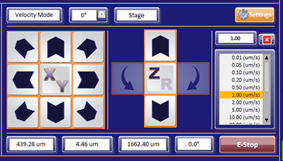

Motion control section of the OmniProbe software, motion arrows are calibrated to the electron image for intuitive operation

Of course even the best hardware would be ineffective without software to match. All OmniProbe’s have intuitive software control, intuitive control means the motion control arrows are calibrated to match the electron image (see image below) and there is also the option with some FIB’s to use controls integrated into the FIB-SEM software. To find out more about OmniProbe applications see our previous blog here our if you would like more details on the product and integrated versions contact us.