This post is the third part of the “Importance of hardware components for EDS” series. In the previous posts, I gave an overview about the SDD and its important role to deliver accurate, fast, and reliable EDS data, and all the components between the SDD and the sample.

I will continue with another important component, the preamplifier.

What’s the role of a preamplifier?

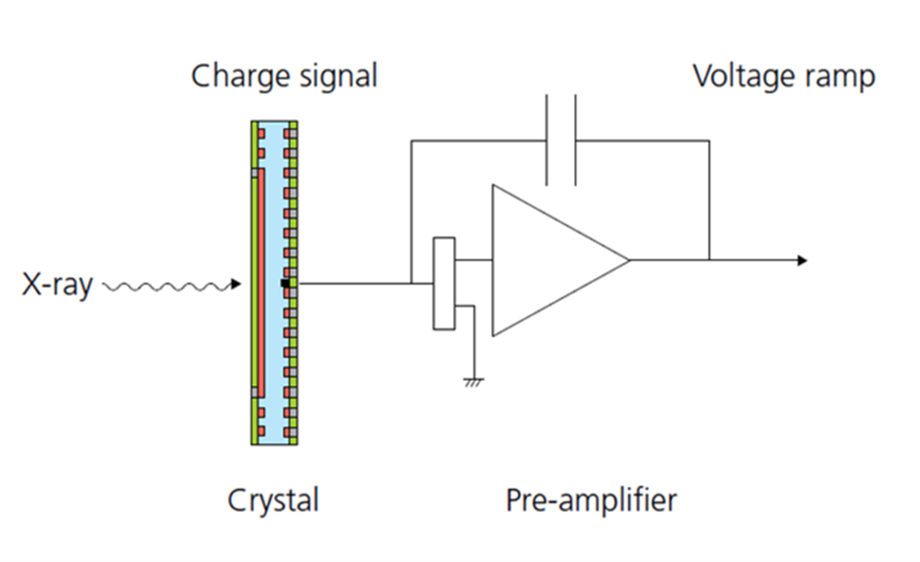

As explained previously, the SDD converts the detected X-ray into an electron cloud that drifts down a field gradient to be collected at the anode. The preamplifier’s role is to convert the accumulated charge at the anode into a voltage signal. It is the first stage of the amplification process that measures the charge liberated in the crystal by an incident X-ray.

This stage of the process is critical to the performance of the EDS detector, as it must convert the signal accurately while introducing as little noise as possible.

Fig. 1. Schematic of SDD connected to preamplifier and feedback capacitor

A key component for optimum speed and low energy sensitivity

Historically, Field Effect Transistor (FET) technology was used. This technology has been improved and developed over time. In the 1980s, Oxford Instruments introduced the PentaFET technology, the first charge reset FET. This technology was a significant advance on existing optically restored FETs, leading to a substantial reduction in noise and the first ever detection of Be by EDS. Nevertheless, with the introduction of SDD sensors in the 2000s, even low noise FETs limited the potential detector performance due to the need to use longer processing times to reduce the voltage noise.

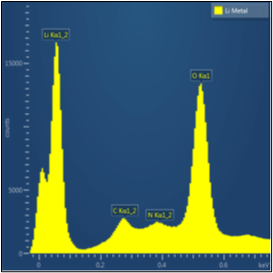

FET technology has since been largely replaced with Charge Sensitive Pre-amplifiers (CSPs) which have a different design and introduce less noise into the voltage signal. This means the count rate at which we can maintain the best resolution has been significantly increased, resulting in an increase in speed of EDS by up to a factor of three. It has also improved the detectability of very low energy X-rays considerably, allowing the first detection of Li (55eV) by EDS (X-Max Extreme).

This new technology is used in the Ultim Max EDS detector range.

Ultim Max EDS detector

Ultim Max EDS detectors combine cutting-edge technologies to deliver the best performance on the market. The acquisition chain, including a non-integrated CSPs preamplifier, has ultra-low noise and provides high sensitivity and stability. This is shown by the unique specification of Ultim Max detectors; all detectors have the same excellent resolution, which is independent of sensor size (from 40mm2 up to 170mm2).

The resolution is guaranteed at low (CK and FK) and high (MnK) energy and for all energies at a productive count rate of 130,000cps. Other detectors offer some of these specifications, but never all, meaning their performance is limited in certain applications.

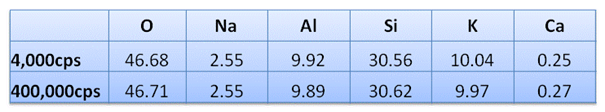

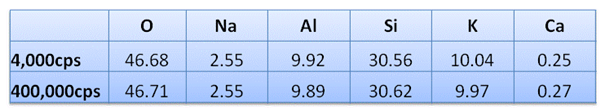

Ultim Max also includes a stability specification that guarantees a change of less than 1eV in peak position and energy resolution between low and high count rates. This means the same quality spectra will be collected, and changes in the spectra will reflect changes in the sample rather than changes in the count rate or microscope parameters used. It also means accurate results can be achieved without compromise at higher count rates (Table 1).

Table 1. Quantitative analysis of an orthoclase standard shows the same accurate results collected at 4,000cps and 400,000cps

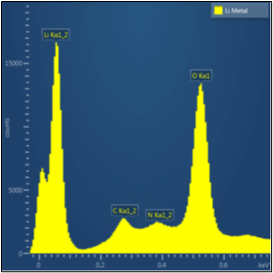

The very low noise provided by our preamplifier technology in Ultim detectors when combined with a windowless design allows for the routine detection of Lithium (55eV – Fig. 2), and other low energy X-rays such as MgL (49eV) using the Ultim Extreme detector.

Fig. 2. X-ray spectrum of a metallic Li film taken at 5kV using an X-Max Extreme windowless detector (reference: Hovington et al. SCANNING VOL.38, 571-578 (2016)). Its successor Ultim Extreme, is still the only large area EDS detector that can detect Li X-rays.

Hopefully, this blog has explained the role of the preamplifier and its importance to obtaining accurate and reliable data. In my next post, I will continue with the cooling system and pulse processor. Join our mailing list to be notified when it goes live.

Join our mailing list