For people performing particle analysis, speed is almost always a crucial factor – along with, of course, accuracy and reliability. The reason for this is that we frequently want to analyse thousands, tens of thousands or even hundreds of thousands of particles in a given analytical run. For each of those particles, a series of (really quite complex) tasks have to be completed in order to ensure that it is correctly analysed and identified. A summary of those tasks could be:

1. Detect the particle (from the mounting medium/background/matrix)

2. Measure the particle morphology

3. Obtain an EDS spectrum

4. Accurately identify the elements present, taking into account and correcting for any effects that could disrupt this process (e.g. peak overlaps, background effects, matrix effects, pulse pile up etc.)

5. Accurately quantify the composition

6. Combine the morphological and compositional data on a particle-by-particle basis

7. Classify the particle on the basis of composition/morphology/both

There are so many steps here because the process seeks to automate what the human eyes and brain would normally do in a manual analysis – most importantly determining what to analyse and then interpreting the results.

There are also a series of tasks that need to be completed both before and after the actual analytical run, in order to both set everything up and then summarise and collate the results into a useful form. These include:

1. Choosing the analytical conditions

2. Setting up a classification scheme

3. Setting up the area that needs to be analysed

4. Ensuring repeatability between runs

5. Collating results and reporting on them

The fact that so much needs to be done could of course slow things down. It also provides many opportunities to employ smart functionalities to make the process easier and faster and to use the information that we have available at different stages in the process to automatically make decisions on what should and shouldn’t be analysed.

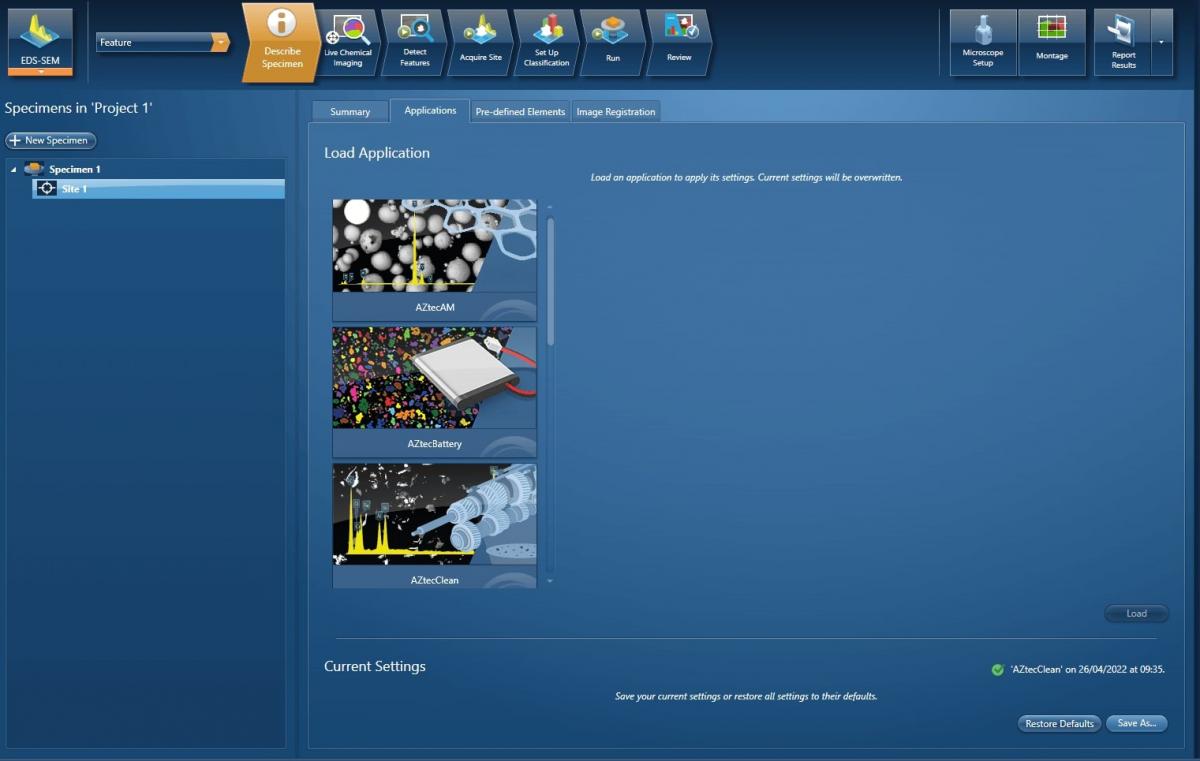

When I perform particle analysis with AZtecFeature, there are several processes that I routinely go through to make my life easier and increase the ease of use and throughput of the process – things like image registration for making the process of setting up a run quicker and easier (see my colleague Lucia’s blog on the topic here) and the use of user profiles (Figure 1) so that I don’t have to determine what analytical settings to use every time I run an analysis.

Figure 1: Multiple profiles containing application recipes in AZtecFeature (profiles shown are AZtecAM for Additive Manufacturing Powders, AZtecBattery for Battery manufacturing powders and AZtecClean for Technical Cleanliness analysis).

There are of course many more things that I can do in addition to these – from single-click reporting once a run has finished to the batch management of multiple runs and, of course, taking advantage of the latest of our FeatureExpress speed increase to minimise the time spent acquiring EDS data (Figure 2).

Figure 2: Extremely fast particle analysis of a geological sample using FeatureExpress fast acquisition in AZtecFeature

Each of these is worthy of a blog in themselves (and many of them have been!) but to really see what effect they can each have, you need to see them being used – to that end, I’ll be giving a tutorial on Thursday 26th May to discuss the many different ways that AZtecFeature ensures high throughput in all aspects of particle analysis – please do join me!