Products

FIB-SEM

Nanomanipulators

OmniProbeOmniProbe CryoSoftware

AZtec3DAZtecFeatureAZtec LayerProbeTEM

Hardware

EDSUltim MaxXplore for TEMImaging

TEM CamerasSoftware

AZtecTEMRaman

RISE

Application Specific Software

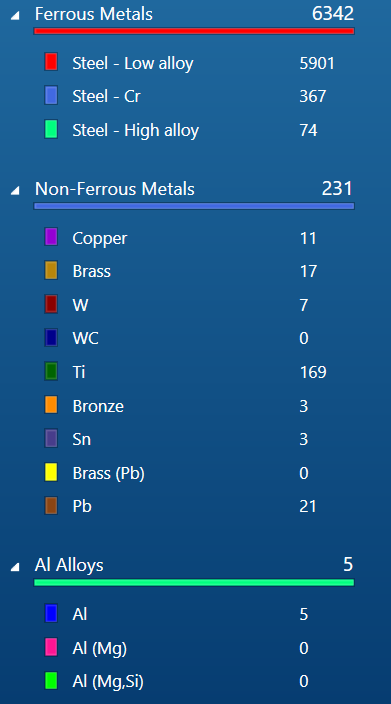

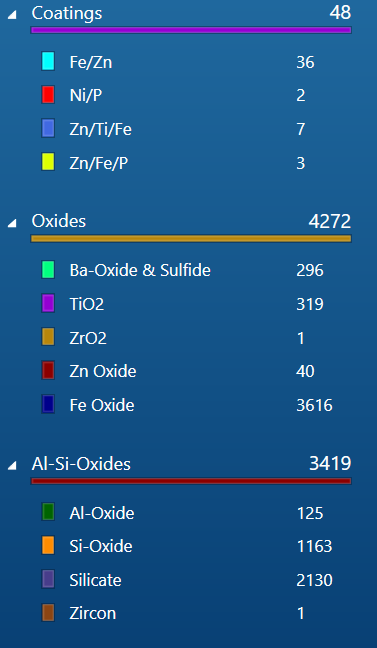

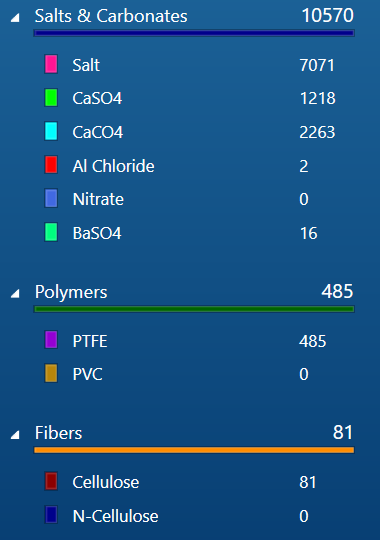

Additive manufacturingAutomated mineralogyBattery materialsCorrelative microscopyFibre analysisGeological materialsGunshot residueHigh Temperature EDS analysisNon-metallic inclusionsParticle AnalysisPharma applicationsTechnical cleanlinessData Processing Software

AZtecFlexAZtecCrystalRelateSample Preparation

Ion Polisher