Cry-lift out

Oxford Instruments OmniProbe cryo lift-out option extends lift-out capability to cryogenic samples, including those prepared by high-pressure freezing.

OmniProbe allows you to work quickly, confidently, and without the risk of sample loss, simplifying advanced workflows and delivering high throughput lift-out. Designed and optimised for TEM lamella preparation in FIB-SEM, our 9th generation nanomanipulators are powered by piezoelectric motors and closed loop control for reliable, repeatable performance.

As our 9th generation of probes, OmniProbe 400 and 350 continue a long-standing tradition of being the highest performance manipulators available for FIB and SEM. Using a compact, port mounted design with sub-nanometre piezoelectric motors the current generation of probes provide a stable platform with low vibration, low drift, and superb positioning accuracy which is combined with our intuitive user interface, where movement direction is calibrated to the image.

The result is the ultimate lift-out and nanomanipulation solution:

Superior linearity - Linearity is a measure of the deviation of the probe tip from the requested movement direction. A probe that moves in a straight line in all directions can

Intuitive user interface where controls directly reflect the movement of probe in the electron image

Smooth continuous motion - Lamella preparation workflows require the probe to make physical contact and smooth motion ensures this can be done without risk of dropping or damaging the sample

Precise movement with stored positions

360° compucentric rotation keeps the probe tip within the microscope field of view

In situ tip change allows probe tips to be replaced fast and without venting the chamber, reducing atmospheric contamination

Stable probe platform - Stability is a combination of vibration and drift. Attaching samples to the probe tip is done by a gas deposition process that can take several minutes. Any drift or vibration of the tip during this process can result in stresses within the sample or sudden movement of the sample at the point it is cut free

Port mounted design retracts fully within the chamber when not in use so there is no compromise to your microscope

Cryogenic tip for biological samples, batteries and more. Lift-out cryogenic samples using the same workflows and as easily as if they were at room temperature

Probe electrical connection includes +/-10V power supply for voltage contrast imaging

Use our handy comparison table below to help you choose the best OmniProbe for your application and to compare specifications.

| SPECIFICATION | OMNIPROBE | ||

| OmniProbe 350 Cryo lift-out | OmniProbe 350 | OmniProbe 400 | |

| Linearity | 500 nm | 500 nm | 250 nm |

| Encoder resolution | <50 nm | <50 nm | 10 nm |

| Insertion repeatability | 15 μm* | 5 μm | 2 μm |

| Min velocity | 50 nm/s | 50 nm/s | 10 nm/s |

| Max Velocity | 250 μm/s | 250 μm/s | 500 μm/s |

| Compucentric rotation | ✘ | ✘ | ✔ |

| Integrated temperature sensor | ✔ | ✘ | ✘ |

| APPLICATION | |||

| Site specific lift-out | ✔ | ✔ | ✔ |

| Plan-view | P | P | ✔ |

| Vent free plan-view | ✘ | ✘ | ✔ |

| Backside Thinning | ✘ | ✘ | P |

| Atom Probe tomography sample preparation | P | P | ✔ |

| Cryogenic liftout | ✔ | ✘ | ✘ |

| Voltage contrast imaging | ✘ | ✔ | ✔ |

| Charge neutralisation | ✔ | ✔ | ✔ |

| On-Tip analysis | ✘ | ✘ | ✔ |

| EBIC measurements | ✘ | O | O |

| EBAC measurements | ✘ | O | O |

| In Situ tip change | ✘ | O | ✔ |

P: Requires an OmniPivot holder O: Available as Option * at constant temperature

The primary application of OmniProbe is site specific lift-out of lamella for TEM. The challenge of lift-out is to extract a sample (lamella), from a milled trench where any unexpected movements can cause sample loss. More precise movement allows smaller features to be targeted and requires less milling for a larger sample.

The addition of 360° rotation with the OmniProbe 400 means additional sample orientations can be prepared, providing thinner samples of higher quality. Compucentric rotation means the sample stays in the centre of the electron image while rotating

Combined probe stage (CSP) recipes enable advanced lift-out to be performed routinely in 3 steps, producing lamella in the optimum geometry.

Linearity of movement is critical for these recipes as the milled trenches can be obscured from view, requiring absolute confidence in the nanomanipulator during lift-out.

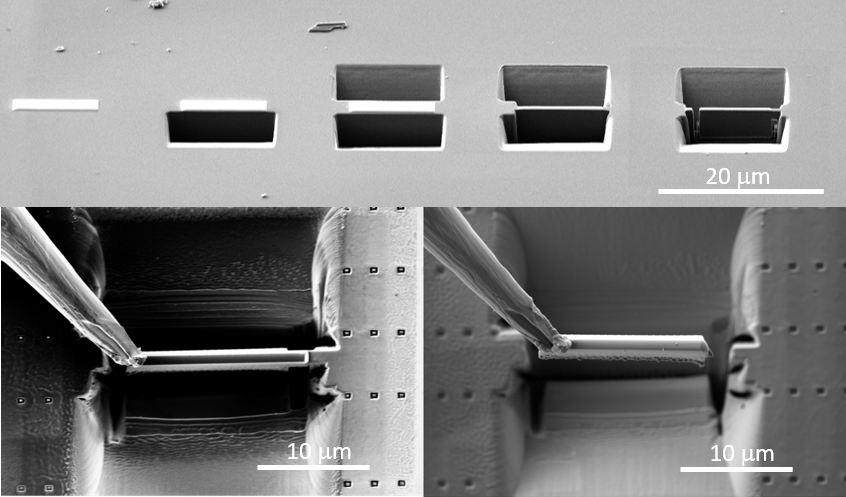

OmniProbe cryo tip and patented workflow means cryogenic TEM lamella can be prepared using the same workflow as a standard lamella. The cryo tip can be passively cooled to below the vitrification point of water, ensuring damage free lift-out.

During the lift-out process the probe tip has material deposited on and milled away it, so over time the tip is consumed. Compucentric rotation of the OmniProbe 400 allows the tip life to be extended by reshaping the tip using the ion beam but even then, it eventually needs replacing. OmniProbe has the unique ability to change the probe tip in minutes, without breaking microscope vacuum, maximising efficiency by minimising down time.

Oxford Instruments OmniProbe cryo lift-out option extends lift-out capability to cryogenic samples, including those prepared by high-pressure freezing.

OmniProbe 350 is a 3-axis, port mounted manipulator featuring piezoelectric motors with closed loop feedback, ideally suited for routine TEM lamella preparation. Precise and intuitive control means you can work quickly and confidently without the risk of damage or sample loss.

A ninth generation of nanomanipulator, the OmniProbe 400 exploits innovative piezo actuation for best in class nanoscale positioning. Optimised for maximum flexibility and performance, the OmniProbe 400 is the ultimate nanomanipulator for high resolution and high throughput applications.