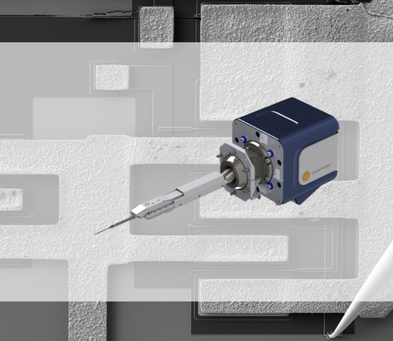

OmniProbe 400

Discover why OmniProbe 400 is the ultimate nanomanipulation solution for high throughput lift-out, offering 4-axis control to simplify advanced workflows

A ninth generation of nanomanipulator, the OmniProbe 400 exploits innovative piezo actuation for best in class nanoscale positioning. Optimised for maximum flexibility and performance, the OmniProbe 400 is the ultimate nanomanipulator for high resolution and high throughput applications.

A ninth generation of nanomanipulator, the OmniProbe 400 exploits innovative piezo actuation for best in class nanoscale positioning. Optimised for maximum flexibility and performance, the OmniProbe 400 is the ultimate nanomanipulator for high resolution and high throughput applications.

Nanoscale manipulation and testing in the SEM and varied lift-out TEM sample preparations in the FIB can be performed easily while using optimized working distances

Nanometre-resolution piezo actuators and 10nm closed-loop encoders provide industry-leading precision, linearity and smooth motion

Automation on multiple levels enables results in the fewest steps possible

The OmniProbe 400 uses a closed-loop control to deliver smooth motion, dependable accuracy, and a high degree of integration. In addition to very high motion resolution, the OmniProbe 400 integrates motorized concentric rotation and fast in situ tip changes as standard:

The tip stays in the field of view for rapid tip shaping and sample reorienting without risk of sample loss or accidental venting.

Discover our comparison table below to help you choose the best OmniProbe for your application and to compare specifications.

| SPECIFICATION | OMNIPROBE | ||

| OmniProbe 350 Cryo lift-out | OmniProbe 350 | OmniProbe 400 | |

| Linearity | 500 nm | 500 nm | 250 nm |

| Encoder resolution | <50 nm | <50 nm | 10 nm |

| Insertion repeatability | 15 μm* | 5 μm | 2 μm |

| Min velocity | 50 nm/s | 50 nm/s | 10 nm/s |

| Max Velocity | 250 μm/s | 250 μm/s | 500 μm/s |

| Compucentric rotation | ✘ | ✘ | ✔ |

| Integrated temperature sensor | ✔ | ✘ | ✘ |

| APPLICATION | |||

| Site specific lift-out | ✔ | ✔ | ✔ |

| Plan-view | P | P | ✔ |

| Vent free plan-view | ✘ | ✘ | ✔ |

| Backside Thinning | ✘ | ✘ | P |

| Atom Probe tomography sample preparation | P | P | ✔ |

| Cryogenic liftout | ✔ | ✘ | ✘ |

| Voltage contrast imaging | ✘ | ✔ | ✔ |

| Charge neutralisation | ✔ | ✔ | ✔ |

| On-Tip analysis | ✘ | ✘ | ✔ |

| EBIC measurements | ✘ | O | O |

| EBAC measurements | ✘ | O | O |

| In Situ tip change | ✘ | O | ✔ |

P: Requires an OmniPivot holder O: Available as Option * at constant temperature

Discover why OmniProbe 400 is the ultimate nanomanipulation solution for high throughput lift-out, offering 4-axis control to simplify advanced workflows

Solar cells are being increasingly used globally and it is important that improvements are made on the production of Mc-Si cells to enhance efficiency. Analysis of these solar cells using EBIC, TEM and APT.