Application Specific Modules

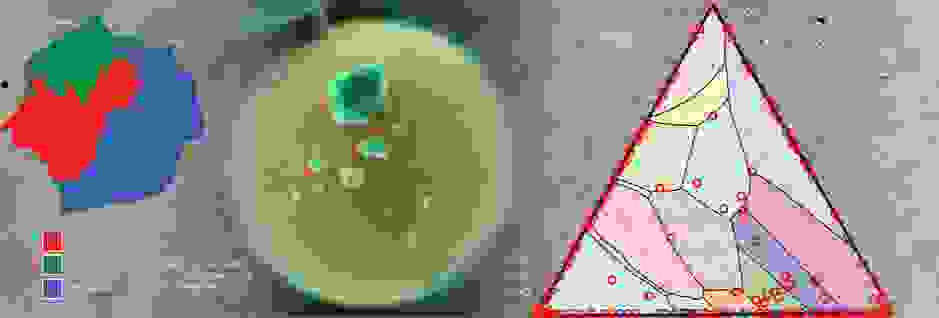

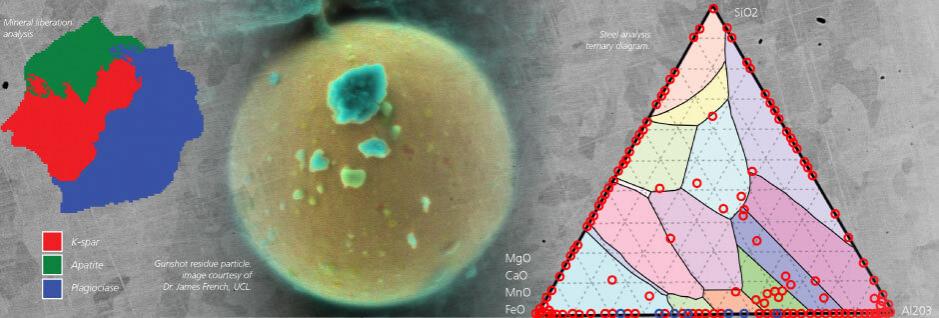

Automated mineralogy - AZtecMineral

The most advanced and cost-effective automated mineralogy system on the market.

- Automatically analyse grain mounts and polished rock sections

- Calculate mineral liberation, modal mineralogy and phase associations

- Directly report phase compositions and compare to assay results

- Use dedicated setups for a range of different ore types

Find out more here: AZtecMineral

Gunshot residue analysis - AZtecGSR

The GSR module adds dedicated setups for crime forensics and gunshot residue analysis. It enables particle classification and reporting according to ASTM 1588-20.

- Classification for all ammunition types

- Reliable identification of gunshot residue particles

- Standard samples for system calibration and optimum repeatability

Find out more here: AZtecGSR

Non-Metallic Inclusions in Steel - AZtecSteel

Analyse inclusions in steels, tyre cords and powder metallurgy...

- Determination of steel cleanliness according to a range of international standards

- Identification and classification of complex inclusions, stringers and clusters

- Comprehensive, automated report generation including statistical data on inclusion types, ternary phase diagrams and plots etc.

Find out more here: AZtecSteel

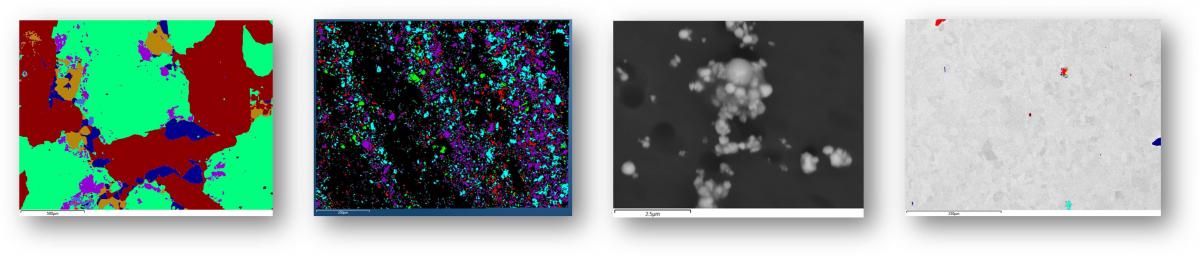

Cleanliness in Battery Manufacture - AztecBattery

Analyse the powders used in the manufacture of Li-ion batteries for the presence of contaminants

- Identify the contaminants by composition and morphology to aid in the process of determining sources and remedial actions

- Easily deployable across multiple sites – ensure consistent cleanliness standards throughout supply chains

- Comprehensive, automated report generation including statistical data on inclusion types, ternary phase diagrams and plots etc.

Find out more here: AZtecBattery

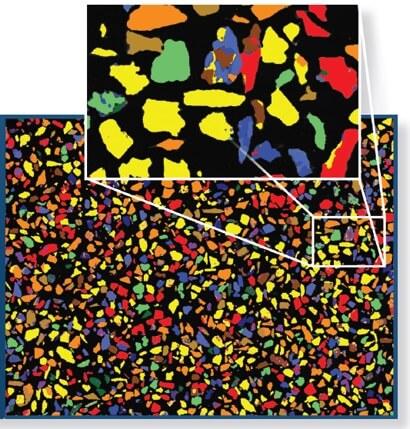

Technical Cleanliness in Automotive Manufacture - AZtecClean

Analyse technical cleanliness samples in automotive manufacture and report results to ISO16232 or VDA 19.

- Identify particles by composition and morphology to aid in the process of determining sources and remedial actions

- Easily deployable across multiple sites – ensure consistent cleanliness standards throughout supply chains

- Report to industry relevant standards including ISO16232 and VDA19 and calculate component cleanliness codes in the software

Find out more here: AZtecClean

Quality Control for Additive Manufacturing Powders - AZtecAM

Analyse metal powders before and after use to maintain quality in your additive manufacturing.

- Identify contaminants so that sources can be identified and fixed

- Monitor previously used powders to determine if they can be recycled again

- Combine with EBSD with Symmetry S2 to check the quality of finished components

Find out more here: AZtecAM

Advanced characterisation

The integration of AZtecFeature with the other modules in the AZtec nanoanalysis suite enables seamless transitions between different techniques and sensors.

For example, if a particle or grain of specific interest is identified during an automated run, it can be relocated and an X-ray or EBSD map acquired in seconds. The advanced AZtec TruMap and TruPhase functionality correct for overlaps and background variations in EDS data and identify phases unambiguously by combining EBSD and EDS data. Alternatively, WDS can be used to determine trace element concentrations or to resolve complex overlaps.

Integration enables:

- Automated pre-screening of samples with AZtecFeature

- Subsequent re-analysis of specific features using alternative techniques

- Combination of Feature analysis with:

- X-ray mapping

- TruMap - removes background and peak overlaps on the fly

- TruMap - removes background and peak overlaps on the fly

- Detailed spectrum analysis with interactive overlaps and element profiles

- Film thickness (LayerProbe)

- EBSD analysis

- TruPhase - combines X-ray and EBSD for unambiguous phase identification

- WDS quantitative analysis

Powered by Bioz

Powered by Bioz